Whirlpool WEG730H0DS Installation Guide - Page 4

Installation Requirements - parts

|

View all Whirlpool WEG730H0DS manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 4 highlights

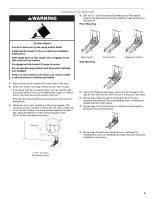

INSTALLATION REQUIREMENTS Tools and Parts Gather the required tools and parts before starting installation. Read and follow the instructions provided with any tools listed here. Tools needed ■ Tape measure ■ Phillips screwdriver ■ Flat-blade screwdriver 3 mm) flat-blade screwdriver ■ Level ■ Pipe-joint compound resistant to LP gas 5 mm) carbide-tipped masonry drill bit (for concrete/ceramic floors) ■ Noncorrosive leak-detection solution ■ Drill For LP/Natural Gas ■ Wrench or pliers Conversions ■ Pipe wrench 1.6 cm)combination wrench 2.4 cm) combination wrench 1 cm) nut driver 3 mm) drill bit (for wood 7 mm) nut driver floors) ■ Masking tape ■ Marker or pencil Parts supplied Check that all parts are included. ■ LP/Natural Gas Conversion Kit ■ 2 - #10 x 1⁵⁄₈" (4.1 cm) screws (for mounting anti-tip bracket) ■ Anti-tip bracket (inside oven cavity) Anti-tip bracket must be securely mounted to the back wall or floor. Thickness of flooring may require longer screws to anchor bracket to subfloor. Longer screws are available from your local hardware store. ■ For model: WEG730H0D KSGG700E KSGB900E MGS8880D WEG760H0D JGS1450D Burner caps 5 5 4 Burner grates 2 2 3 Oven racks 2 3 3 Parts needed Check local codes and consult gas supplier. Check existing gas supply and electrical supply. See "Electrical Requirements" and "Gas Supply Requirements" sections. Optional Parts To purchase these or any other accessories, please reference the "Accessories" section of the User Guide for contact information. ■ Side Trim Kits: White - Order Part Number W10677527 Black - Order Part Number W10675026 Stainless Steel - Order Part Number W10675028 ■ Backsplash Kits: High 6" (15.2 cm) White - Order Part Number W10655448 High 6" (15.2 cm) Black - Order Part Number W10655449 High 6" (15.2 cm) Stainless Steel - Order Part Number W10655450 Location Requirements IMPORTANT: Observe all governing codes and ordinances. Do not obstruct flow of combustion and ventilation air. ■ It is the installer's responsibility to comply with installation clearances specified on the model/serial rating plate. The model/serial rating plate is located behind the oven door on the top right-hand side of the oven frame. ■ The range should be located for convenient use in the kitchen. ■ Recessed installations must provide complete enclosure of the sides and rear of the range. ■ To eliminate the risk of burns or fire by reaching over heated surface units, cabinet storage space located above the surface units should be avoided. If cabinet storage is to be provided, the risk can be reduced by installing a range hood or microwave hood combination that projects horizontally a minimum of 5" (12.7 cm) beyond the bottom of the cabinets. ■ All openings in the wall or floor where range is to be installed must be sealed. ■ Cabinet opening dimensions that are shown must be used. Given dimensions are minimum clearances. ■ The anti-tip bracket must be installed. To install the anti-tip bracket shipped with the range, see "Install Anti-Tip Bracket" section. ■ Grounded electrical supply is required. See "Electrical Requirements" section. ■ Proper gas supply connection must be available. See "Gas Supply Requirements" section. ■ Contact a qualified floor covering installer to check that the floor covering can withstand at least 200°F (93°C). ■ Use an insulated pad or ¼" (0.64 cm) plywood under range if installing range over carpeting. IMPORTANT: To avoid damage to your cabinets, check with your builder or cabinet supplier to make sure that the materials used will not discolor, delaminate or sustain other damage. This oven has been designed in accordance with the requirements of UL and CSA International and complies with the maximum allowable wood cabinet temperatures of 194°F (90°C). 4