Ariens Deluxe Track 28 Owners Manual - Page 25

Check Auger Gearcase, General Lubrication

|

View all Ariens Deluxe Track 28 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 25 highlights

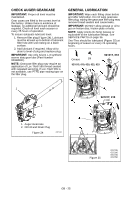

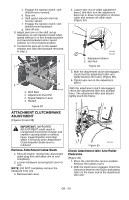

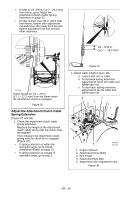

CHECK AUGER GEARCASE IMPORTANT: Proper oil level must be maintained. Gear cases are filled to the correct level at the factory. Unless there is evidence of leakage, no additional lubricant should be required. Check oil level each season or every 25 hours of operation. To ensure adequate lubricant level: 1. Remove filler plug (Figure 24). Lubricant must be at least up to bottom of lubricant filler hole with unit resting on a levelsurface. 2. Add lubricant if required. Allow oil to drain to level of plug and replace plug. IMPORTANT: Use only Ariens L-3 synthetic severe duty gear lube (Part Number 00068800). NOTE: Gearcase filler plug may require an application of Loc-Tite® 565 thread sealant with repeated servicing. If Loc-Tite® 565 is not available, use PTFE pipe sealing tape on the filler plug. GENERAL LUBRICATION IMPORTANT: Wipe each fitting clean before and after lubrication. Do not wipe gearcase filler plug; wiping the gearcase filler plug may remove thread sealant and cause leaks. IMPORTANT: DO NOT allow grease or oil to get on friction disc, friction plate or belts. NOTE: Apply Ariens Hi-Temp Grease or equivalent to the lubrication fittings. See SERVICE PARTS on page 36. Sno-Thro should be lubricated (Figure 25) at beginning of season or every 25 operating hours. Grease Oil 921013, 019, 020, 022, 023 921017, 018 1 2 921017, 018 1. Auger Gearcase 2. Oil Fill and Drain Plug Figure 24 OS7132 Figure 25 OS7235 OS7240 OS7245 OS7250 GB - 25