Ariens Deluxe Track 28 Owners Manual - Page 34

Friction Disc Replacement

|

View all Ariens Deluxe Track 28 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 34 highlights

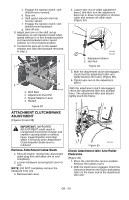

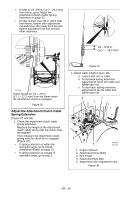

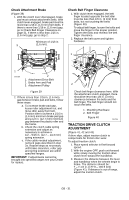

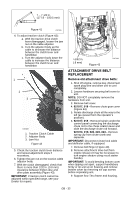

2. To gain belt clearance, remove swing gate spacer and slide drive plate over so that finger clears stop hole in frame and can swing past it (Figure 46). 3. Pull idler away from traction drive belt and remove belt from idler pulley, engine sheave and driven pulley (it may be necessary to turn engine pulley using recoil handle). 7 8 2 3 5 1 6 4 OS7144 1. Spacer 2. Drive Plate Assembly 3. Traction Belt Idler 4. Attachment Drive Belts 5. Traction Drive Belt 6. Engine Sheave 7. Friction Disc 8. Drive Plate Finger Figure 46 4. Install new traction drive belt onto driven pulley and engine sheave. 5. Swing drive plate toward friction disc until finger lines up with stop hole in frame. Slide drive plate over, inserting finger into stop hole. Reinstall drive plate spacer. NOTE: Make sure the drive plate assembly return spring remains connected to the frame and nylon bushing is in drive plate pivot hole. 6. Replace attachment drive belt (See Attachment Drive Belt Replacement on page 32). FRICTION DISC REPLACEMENT 1. Shut off engine, remove key, disconnect spark plug wire and allow unit to cool completely. 2. Place unit into service position on a level surface. 3. Remove both wheels. 4. Remove bottom cover by removing six hex bolts. 5. Disconnect pivot pin from the speed selector arm. Save the hardware for reinstallation. 6. Remove spring clip nearest drive sprocket from hex shaft. 7. Remove left bearing flange from frame. 8. Slide hex shaft to the left to remove pinion sprocket and friction disc assembly from hex shaft. NOTE: Be sure to save washers between bearing and sliding fork for re-assembly. 9. Remove friction disc assembly from frame. 10. Remove three screws holding friction disc to carrier bearing. 11. Remove old friction disc. Put the new friction disc in place, cup side to carrier bearing. 12. Reinstall three screws onto new friction disc and carrier bearing. Torque to 5 - 6 lbf-ft (22.2 - 26.7 N•m). 13. Insert new friction disc assembly into frame. Install washers onto carrier bearing and slide into speed selector arm. 14. Slide hex shaft through new friction disc assembly. Install pinion sprocket onto hex shaft and slide shaft into right bearing. 15. Install left bearing using hardware removed in step 7. 16. Reinstall clip pin into hex shaft. 17. Connect pivot pin to speed selector arm (see Discharge Chute on page 28). 18. Replace bottom cover. 19. Install wheels. 20. Return unit to upright position. 21. Connect spark plug wire to spark plug. 22. Adjust traction drive clutch (see Traction Drive Clutch Adjustment on page 31). GB - 34