Bernina 530 Manual - Page 53

Useful, Hints

|

View all Bernina 530 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 53 highlights

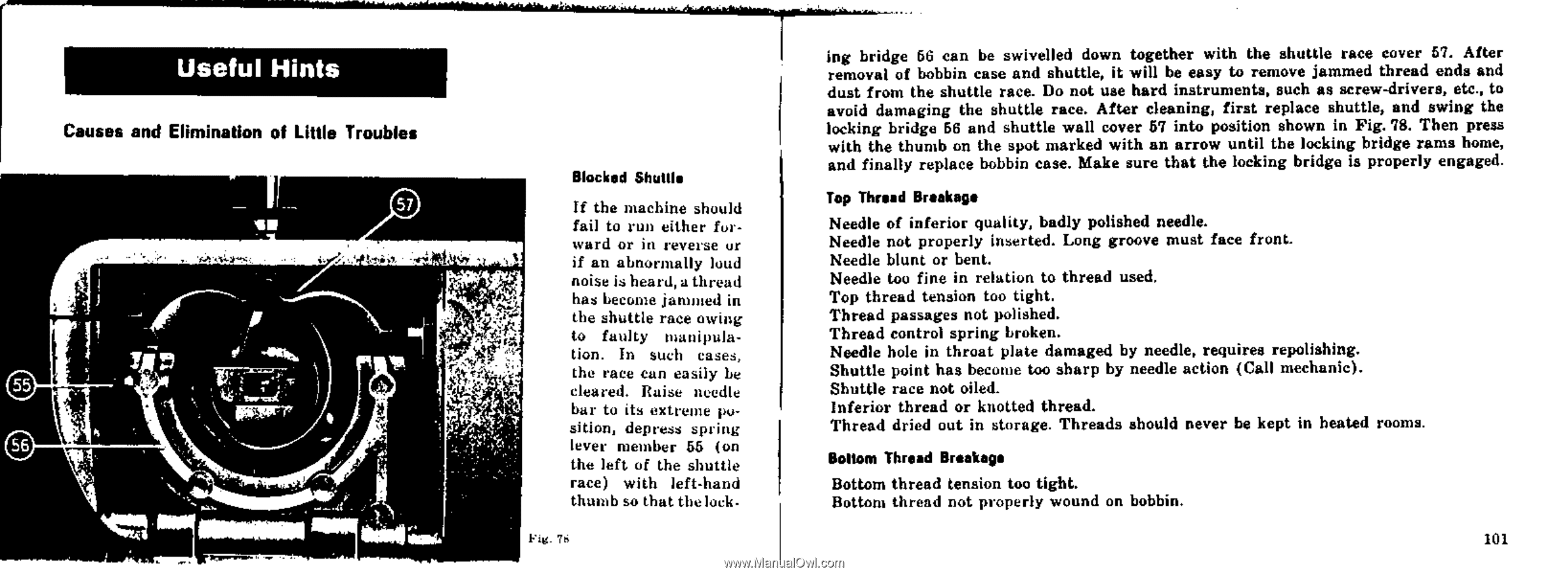

Useful Hints Causes and Elimination of Little Troubles 57 'E VT7i , 4 ...Z.( • It Blocked Shells If the machine should fail to run either furward or in reverse or if an abnormally loud noise is heard, a thread has become jammed in the shuttle race owing to faulty manipulation. In such cases, the race can easily be cleared. Raise needle bar to its extreme position, depress spring lever member 55 inn the left of the shuttle race) with left-hand thumb so that the lock- Fig. 7, ing bridge 56 can be swivelled down together with the shuttle race cover 57. After removal of bobbin case and shuttle, it will be easy to remove jammed thread ends and dust from the shuttle race. Do not use hard instruments, such as screw-drivers, etc., to avoid damaging the shuttle race. After cleaning, first replace shuttle, and swing the locking bridge 66 and shuttle wall cover 57 into position shown in Fig. 78. Then press with the thumb on the spot marked with an arrow until the locking bridge rams home, and finally replace bobbin case. Make sure that the locking bridge is properly engaged. Top Thread Breakage Needle of inferior quality, badly polished needle. Needle not properly inserted. Long groove must face front. Needle blunt or bent. Needle too fine in relation to thread used, Top thread tension too tight. Thread passages not polished. Thread control spring broken. Needle hole in throat plate damaged by needle, requires repolishing. Shuttle point has become too sharp by needle action (Call mechanic). Shuttle race not oiled. Inferior thread or knotted thread. Thread dried out in storage. Threads should never be kept in heated rooms. Bolton' Thread Breakage Bottom thread tension too tight. Bottom thread not properly wound on bobbin. 101