Bernina Bernette 20 Operation Manual - Page 4

Sewing Machine Needles

|

View all Bernina Bernette 20 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 4 highlights

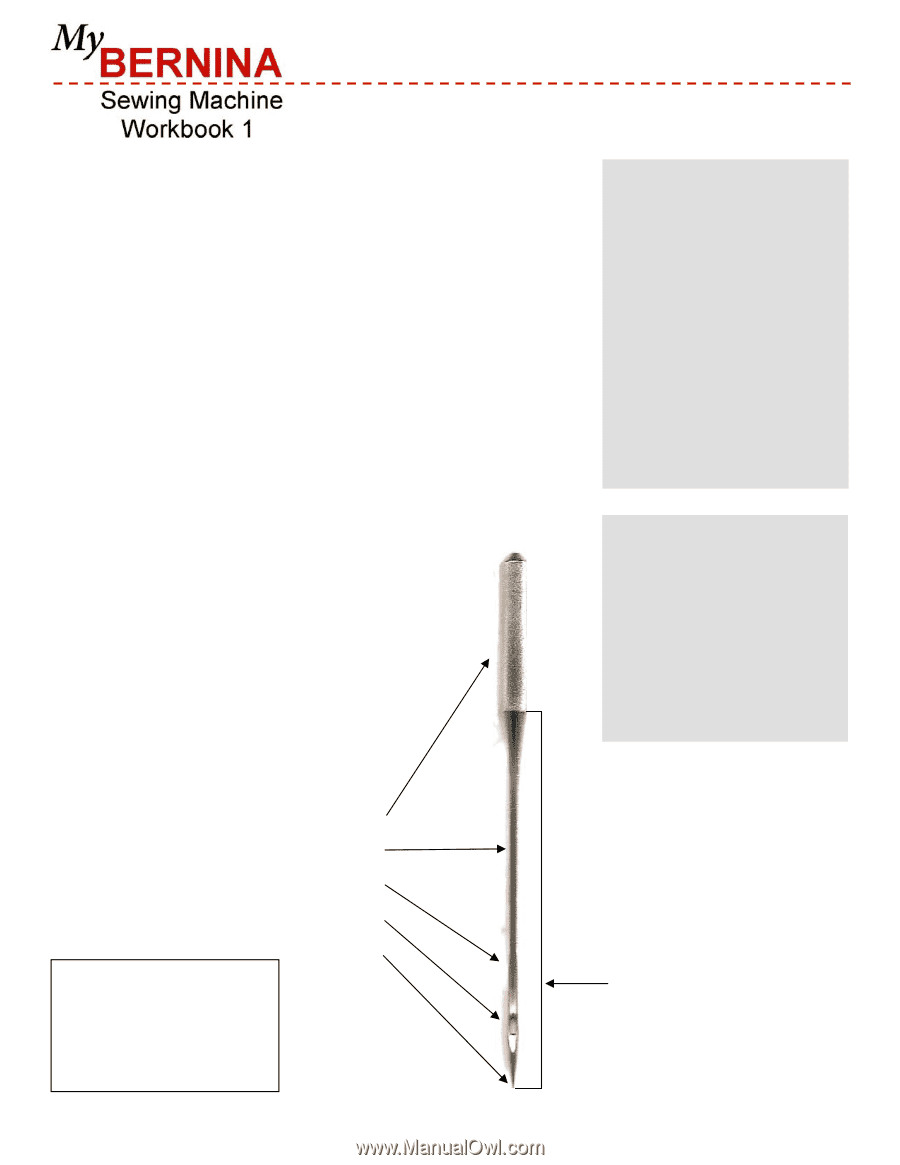

Sewing Machine Needles General Information Along with thread, needles are very important to stitch formation. Many "mechanical" problems and damage to fabrics can be traced to a bent, damaged, or incorrect size or type needle. When selecting the correct needle, consider the following: Needle system - 130/705H Needle point - assures proper stitch formation; avoids fabric damage Needle size - smaller for lightweight fabrics; larger for heavier fabrics If the needle is: Too small - the thread can't stay in the groove to form a loop to be picked up by the hook point Bent - the thread loop forms too far away from hook point and the hook can't enter the loop to form a stitch Blunt - the needle won't pierce fabric, so no thread loop forms to make a stitch Need to Know Needles should be changed after every 4-6 hours of stitching. The needle is the most inexpensive part in your sewing machine but it is crucial for getting good results and keeping your machine running well. Don't let false economy keep you from doing what is best for your sewing projects and your machine. Parts of a Needle Shank (flat side to the back) Groove (on the front) Scarf (on the back) Needle Size for Fabrics 60 - very fine batiste 70 - shirt-weight 80 - medium-weight 90 - denim and twill 100/110/120 - canvas Eye Point 12/13/10 Needle "Secret" Code • DRI = Triple • E = Embroidery • J = Jeans • L, LL, R = Leather • M = Microtex • MET = Metallica • N = Topstitching/Cordonnet • Q = Quilting • S = Stretch • SUK = Fine Ball Point • SES = Medium Ball Point • WING = Wing • ZWI = Double Needle Size Conversion Regardless of the system, the greater the number, the larger the diameter of the needle. European vs. Domestic 60 = 8 70 = 10 75 = 11 80 = 12 90 = 14 100 = 16 110 = 18 120 = 19 The selected thread should fit in the groove on the front of the needle. If it isn't protected by the groove, a needle with a larger groove should be used. Always make sure needles are fully inserted as high as possible, with the flat side to the back. Shaft 4