Craftsman 21419 Operation Manual - Page 9

Pto M, Action

|

View all Craftsman 21419 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 9 highlights

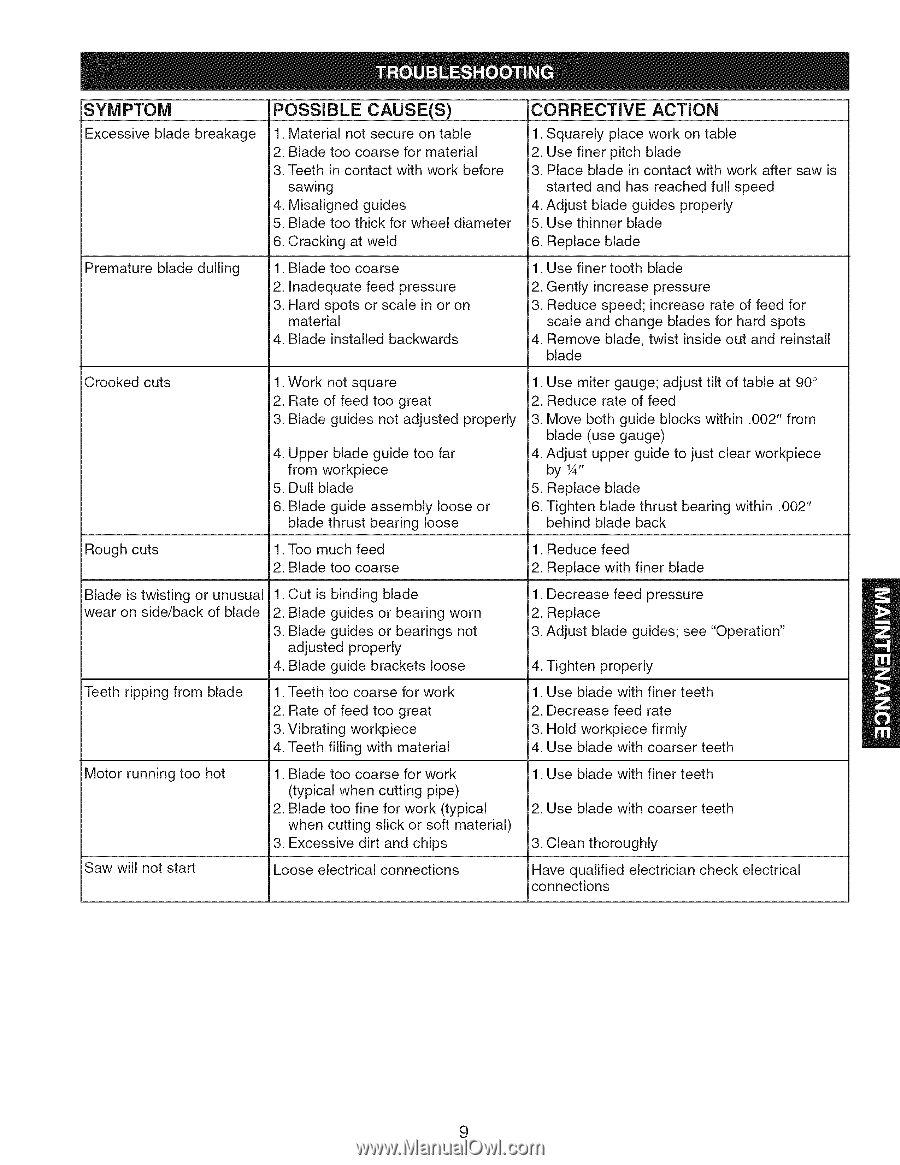

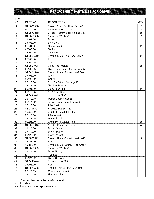

SYMPTO M Excessive blade breakage Premature blade dulling POSSIBLE CAUSE(S) 1. Material not secure on table 2. Blade too coarse for material 3. Teeth in contact with work before sawing 4. Misaligned guides 5. Blade too thick for wheel diameter 6. Cracking at weld 1. Blade too coarse 2. Inadequate feed pressure 3. Hard spots or scale in or on material 4. Blade installed backwards CORRECTIVE ACTION 1 •Squarely place work on table 2. Use finer pitch blade 3. Place blade in contact with work after saw is started and has reached full speed 4. Adjust blade guides properly 5. Use thinner blade 6. Replace blade 1 •Use finer tooth blade 2. Gently increase pressure 3. Reduce speed; increase rate of feed for scale and change blades for hard spots 4. Remove blade, twist inside out and reinstall blade Crooked cuts Rough cuts 1. Work not square 2. Rate of feed too great 3. Blade guides not adjusted properly 4. Upper blade guide too far from workpiece 5. Dull blade 6. Blade guide assembly loose or blade thrust bearing loose 1. Too much feed 2. Blade too coarse 1. Use miter gauge; adjust tilt of table at 90 ° 2. Reduce rate of feed 3. Move both guide blocks within .002" from blade (use gauge) 4. Adjust upper guide to just clear workpiece byW' 5. Replace blade 6. Tighten blade thrust bearing within •002" behind blade back 1. Reduce feed 2. Replace with finer blade Blade is twisting or unusual wear on side/back of blade 1. Cut is binding blade 2. Blade guides or bearing worn 3. Blade guides or bearings not adjusted properly 4. Blade guide brackets loose Teeth ripping from blade 1. Teeth too coarse for work 2. Rate of feed too great 3. Vibrating workpiece 4. Teeth filling with material Motor running too hot 1. Blade too coarse for work (typical when cutting pipe) 2. Blade too fine for work (typical when cutting slick or soft material) 3. Excessive dirt and chips Saw will not start Loose electrical connections 1. Decrease feed pressure 2. Replace 3. Adjust blade guides; see "Operation" 4. Tighten properly 1. Use blade with finer teeth 2. Decrease feed rate 3. Hold workpiece firmly 4. Use blade with coarser teeth 1. Use blade with finer teeth 2. Use blade with coarser teeth 3. Clean thoroughly Have qualified electrician check electrical connections 9