Cub Cadet ZTX4 54 Operation Manual - Page 8

Position Lapbar Drive Control Levers, Setting Front Gauge Wheels, Battery Information

|

View all Cub Cadet ZTX4 54 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 8 highlights

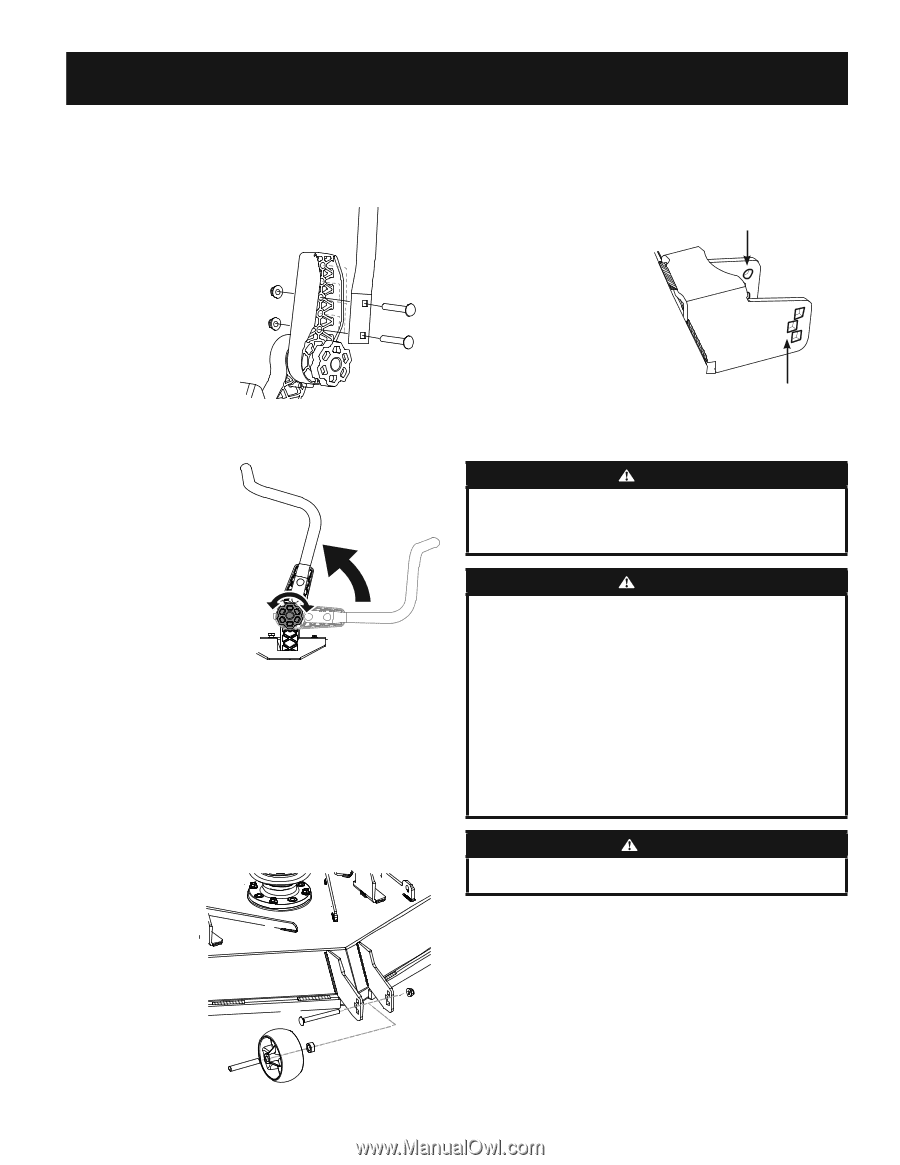

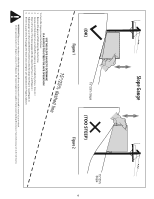

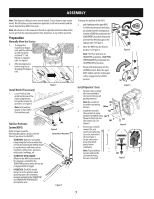

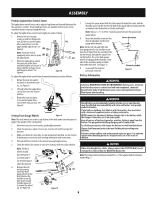

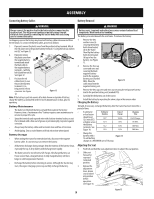

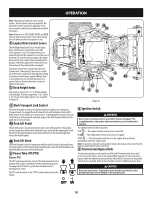

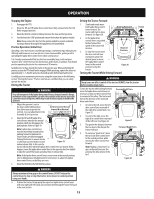

ASSEMBLY Position Lapbar Drive Control Levers The lapbar drive control levers can be adjusted up/down and forward/backward for the operator's comfort. Three height positions are available and/or levers can be rotated forward or rearward using the knob. To adjust the lapbar drive control lever height, proceed as follows: 1. Remove the two carriage screws (a) and two flange lock nuts (b) that secure the lapbar drive control lever (c) to the upper handle adjuster (d). See Figure 8. (b) Note: The multi-tool (if equipped) can be used to make (b) this adjustment. 2. Move the lapbar drive control lever into one of the three available heights and secure in place with the carriage screws and flange lock nuts. See Figure 8. (d) (c) (a) (a) Figure 8 To adjust the lapbar drive control levers forward/rearward, proceed as follows: 7. Line up the gauge wheel with the tube spacer through the center, and the shoulder spacer on the shorter side hub of the gauge wheel, and position the assembly inside the brackets at the desired height. Note: Allow a 6.35-12.7 mm)clearance between the ground and gauge wheel. 8. Insert the shoulder screw into the Inner bracket chosen index hole on the front gauge wheel bracket. Note: On the left side and right side deck gauge wheels, the shoulder screw must be installed from the outside of the tractor inward, through the square hole on the bracket. On center deck gauge wheels (if equipped) the shoulder screw side of the assembly can be installed from either direction. See Figure 11. 9. Secure with the lock nut previously removed. Outer bracket Figure 11 Battery Information 1. Rotate the knob (a) counterclockwise to loosen the knob (a). See Figure 9. 2. Lift and rotate the lapbar drive control lever into the desired position. WARNING California PROPOSITION 65 WARNING: Battery posts, terminals, and related accessories contain lead and lead compounds, chemicals known to the State of California to cause cancer and reproductive harm. Wash hands after handling. 3. Rotate the knob clockwise to secure the lapbar drive control lever into position. See Figure 9. (a) Setting Front Gauge Wheels Figure 9 Note: The deck wheels are an anti-scalp feature of the deck and are not designed to support the weight of the cutting deck. 1. Move the tractor to a level surface, preferably pavement. 2. Check tire pressure, adjust, if necessary. See tire side wall for proper tire pressure. 3. Make sure the deck is level side-to-side and properly pitched. See the Service & Maintenance section for deck leveling information and instructions. WARNING Should battery acid accidentally splatter into the eyes or onto the skin, rinse the affected area immediately with clean cold water. Seek prompt medical attention. If acid spills on clothing, first dilute it with clean water, then neutralize with a solution of ammonia/water or baking soda/water. NEVER connect (or disconnect) battery charger clips to the battery while the charger is turned on, as it can cause sparks. Keep all sources of ignition (cigarettes, matches, lighters) away from the battery. The gas generated during charging can be combustible. As a further precaution, only charge the battery in a well ventilated area. Always shield eyes and protect skin and clothing when working near batteries. Batteries contain sulfuric acid and may emit explosive gases. Use extreme caution when handling batteries. Keep batteries out of the reach of children. 4. Place deck lift lever or knob in the desired mowing height position. 5. Check the wheels for contact or excessive clearance with the surface below. CAUTION Note: The deck wheels should have between ¼" (6.35mm) and ½" (12.7mm)clearance above the ground. 6. Remove the lock nut (a) securing one of the front gauge wheels to the deck. Remove the shoulder screw (b), tube spacer (c) and shoulder spacer (e) to remove the wheel (d) See Figure 10. (b) (e) (d) (c) Figure 10 When attaching battery cables, always connect the POSITIVE (Red) wire to terminal first, followed by the NEGATIVE (Black) wire. Note: The positive battery terminal is marked Pos. (+). The negative battery terminal is marked Neg. (-). (a) 8