Hayward TriStar® VS Owners Manual - Page 5

Installation & Wiring, ATTENTION, WARNING

|

View all Hayward TriStar® VS manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 5 highlights

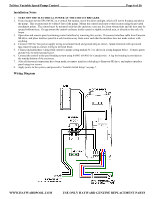

TriStar Variable Speed Pump Control ____ Page 5 of 16 Installation & Wiring ATTENTION - Refer to TriStar Owner's Guide (IS3200) for all applicable pump installation, operation, and troubleshooting information. Electrical WARNING - All electrical wiring MUST conform to local codes, regulations, and the National Electric Code (NEC). WARNING - Ground and bond control and motor before connecting to electrical power supply. Failure to ground and bond control and motor can cause serious or fatal electrical shock hazard. Do NOT ground to a gas supply line. To avoid dangerous or fatal electrical shock, turn OFF power to control and motor before working on electrical connections. Fire Hazard - match supply voltage to control and motor nameplate voltage. Insure that the electrical supply available agrees with the control and motor's voltage, phase, and cycle, and that the wire size is adequate for the HP (kW) rating and distance from the power source. Use copper conductors only. Line Power Supply Specs Voltage: 230VAC, 60 Hz, Single Phase Breaker: 20 amps Wire Size: 12 AWG Use copper conductors only. For indoor/outdoor use. A disconnecting means located within sight of this control, and at least 5 ft. from the inside wall of the pool, spa, or hot tub, must be provided. Voltage Voltage at control and motor MUST NOT be more than 10% above or below motor name plate rated voltage, or components may overheat, causing overload tripping and reduced component life. If voltage is less than 90% or more than 110% of rated voltage when motor is running at full load, consult power company. Grounding And Bonding Install, ground, bond, and wire control and motor in accordance with local or national electrical code requirements. Permanently ground control and motor. Use green ground terminal provided under motor canopy or access place; use size and type wire required by code. Connect control and motor ground terminals to control enclosure ground. Bond control and motor to pool structure. Bonding will connect all metal parts within and around the pool with a continuous wire. Bonding reduces the risk of a current passing between bonded metal objects, which could potentially cause electrical shock if grounded or shorted. Reference NEC codes for all wiring standards including, but not limited to, grounding, bonding and general wiring procedures. Use a solid copper conductor, size 8 or larger. Run wire from external bonding lug to reinforcing rod or mesh. Connect a No. 8 AWG (8.4 mm2) solid copper bonding wire to the pressure wire connector provided on the control and motor housings and to all metal parts of swimming pool, spa, or hot tub, and to all electrical equipment, metal piping (except gas piping), and conduit within 5 ft. (1.5 m) of inside walls of swimming pool, spa, or hot tub. Wiring WARNING - All electrical wiring MUST conform to local codes, regulations, and the National Electric Code (NEC). Control and pump MUST be permanently connected to circuit. If other lights or appliances are also on the same circuit, be sure to add their amp loads before calculating wire and circuit breaker sizes. Use the load circuit breaker as the Master OnOff switch. If the variable speed pump and control are being used to replace an existing pump that was controlled by a separate mechanical time clock, the control should be connected directly to the line power supply, bypassing the time clock. The time clock can then be used to power other equipment (such as a heater, heat pump, or booster pump) that requires the filter pump to be operating when used. If the time clock is used in this manner, it should be set to power the equipment during a time cycle when the variable speed pump is operating at an appropriate flow rate, as defined by the steps set in the sequencer menu. WWW.HAYWARDPOOL.COM USE ONLY HAYWARD GENUINE REPLACEMENT PARTS