HP Latex 110 Introductory information - Page 3

Electrical shock hazard, Heat hazard, Fire hazard, Mechanical hazard

|

View all HP Latex 110 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 3 highlights

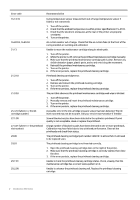

• The printer has been dropped or the curing module has been damaged. • The printer is not operating normally. Turn off the printer in either of the following cases: • During a thunderstorm • During a power failure Take special care with zones marked with warning labels. Electrical shock hazard WARNING! The internal circuits of curing zones, vapor removal, print zone heaters and built-in power supplies operate at hazardous voltages capable of causing death or serious personal injury. The printer uses two power cords. Unplug both power cords before servicing the printer. To avoid the risk of electric shock: • The printer must be connected to earthed mains outlets only. • Do not attempt to dismantle the curing modules. • Do not remove or open any other closed system covers or plugs. • Do not insert objects through slots in the printer. Heat hazard The curing subsystems of the printer operate at high temperatures and can cause burns if touched. To avoid personal injury, take the following precautions. • Do not touch the internal enclosures of the printer's curing zones. • Let the printer cool down when accessing to internal curing zone and output platen in case of substrate jam. • Let the printer cool down before performing some maintenance operations. Fire hazard The curing subsystems of the printer operate at high temperatures. To avoid the risk of fire, take the following precautions. • The customer is responsible for meeting the printer's requirements and the Electrical Code requirements according to the local jurisdiction of the country where the equipment is installed. Use the power supply voltage specified on the nameplate. • Connect the power cords to dedicated lines, each protected by a branch circuit breaker according to the information in the site preparation guide. Do not use a power strip (relocatable power tap) to connect both power cords. • Use only the power cords supplied by HP with the printer. Do not use a damaged power cord. Do not use the power cords with other products. • Do not insert objects through slots in the printer. • Take care not to spill liquid on the printer. After cleaning, make sure all components are dry before using the printer again. • Do not use aerosol products that contain flammable gases inside or around the printer. Do not operate the printer in an explosive atmosphere. • Do not block or cover the openings in the printer body. • Do not attempt to dismantle or modify the curing modules. • Ensure that the operating temperature of the substrate, as recommended by its manufacturer, is not exceeded. If this information is not available, ask the manufacturer. Do not load substrates that cannot be used at an operating temperature above 125°C (257°F). • Do not load substrates with auto-ignition temperatures below 250°C (482°F). If this information is not available, printing must be supervised at all times. See note below. NOTE: Test method based on EN ISO 6942:2002: Evaluation of materials and material assemblies when exposed to a source of radiant heat, method B. The test conditions to determine the temperature when the substrate starts ignition (either flame or glow) were: Heat flux density: 30 kW/m², copper calorimeter, K-type thermocouple. Mechanical hazard The printer has moving parts that could cause injury. To avoid personal injury, take the following precautions when working close to the printer. Introductory Information 2