Husqvarna 316EL Owners Manual - Page 13

Mounting guide bar and chain, Chain oil

|

View all Husqvarna 316EL manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 13 highlights

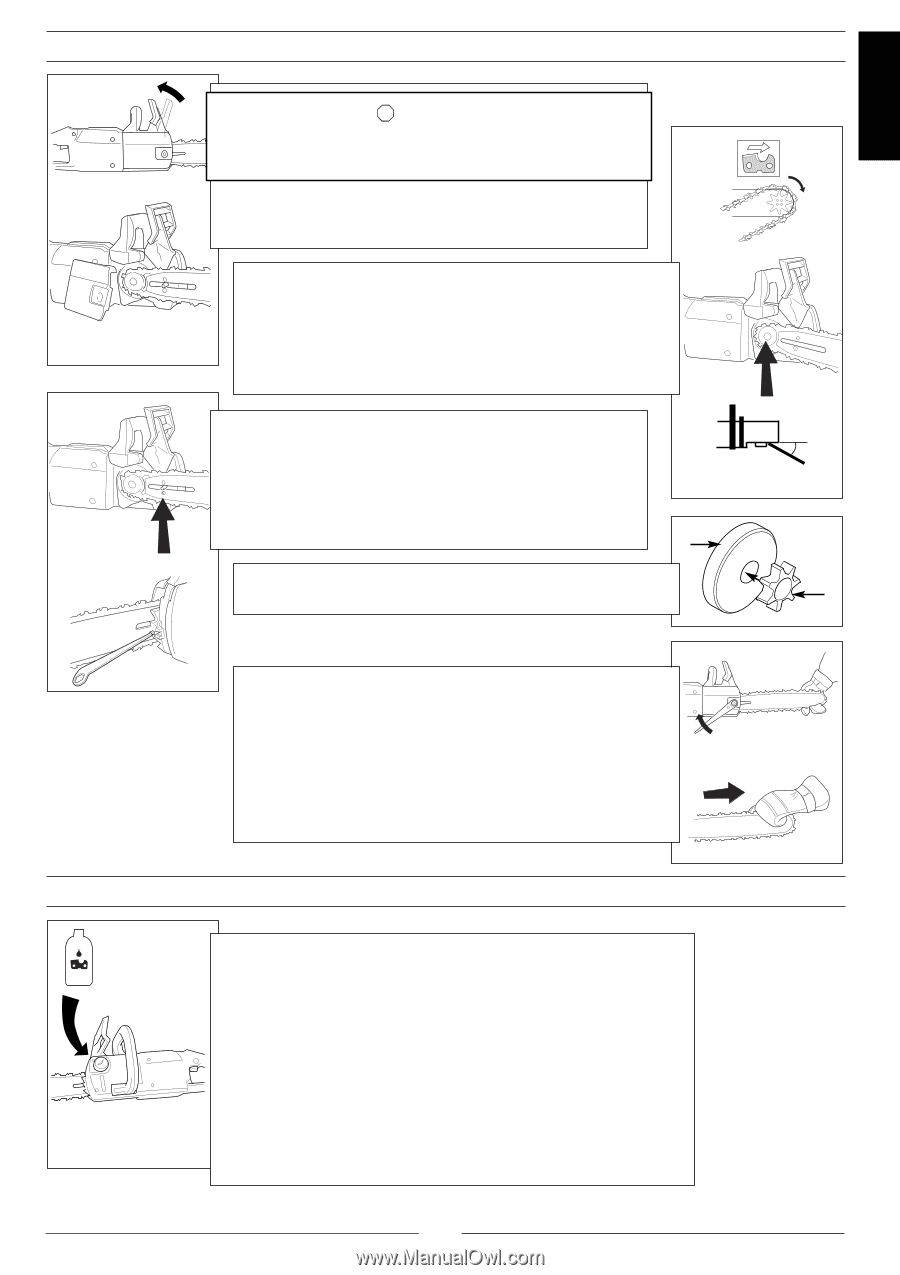

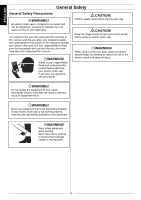

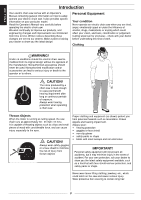

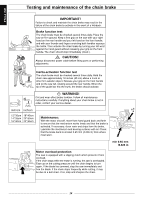

Mounting guide bar and chain STOP WARNING! Always pull out the plug before fitting parts or adjusting the saw. Wear gloves when working with the chain in order to protect your hands from injury. Check that the chain brake is disengaged by moving the front hand guard towards the front handle. Take off the bar nuts and remove the clutch cover. Fit the chain around guide bar nose with the top cutters facing forwards. Holding the chain over the guide bar nose, position the back end of the guide bar against the drive sprocket at a 45° angle to the power head. Pass the free end of the chain around the drive sprocket, swing the guide bar into place over the mounting bolt and against the power head, and guide the chain into the guide bar groove. Seat the guide bar on the adjusting pin and replace the clutch cover. Check that the drive links fit correctly on the drive sprocket and that the chain is in the groove on the bar. Tighten bar nuts finger tight. Adjust chain tension, using combination wrench to turn adjustment screw clockwise to tighten. Tighten adjustment screw until the chain is drawn snugly against the underside of the bar. A A Clutch B Drive sprocket. Support the tip of the bar while adjusting the chain. Chain tension is correct when there is no slack on the underside of the bar, but the chain may still be turned easily by hand. Hold up the bar tip and tighten the bar nuts with the combination wrench. When a new chain has been fitted, check tension frequently until the chain has been broken in. Check chain tension regularly. A chain that is correctly adjusted gives good cutting performance and lasts longer. Chain oil Chain oil Chain oil • The chain lubrication system is automatic. Always use special chain oil with good adhesive characteristics. • In countries where no special chain oil is available, gear oil EP 90 may be used. • Never use waste oil. Doing so may result in damage to the chain, bar and oil pump. • It is important to use oil of the correct viscosity appropriate to the air temperature. • In temperatures below 0°C (32°F) some oils become more sluggish. That puts an added strain on the oilpump and may cause damage to oil pump parts. • Contact your service dealer for help in choosing the right chain oil. 11