Husqvarna 316EL Owners Manual - Page 20

Approved bar / chain combinations

|

View all Husqvarna 316EL manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 20 highlights

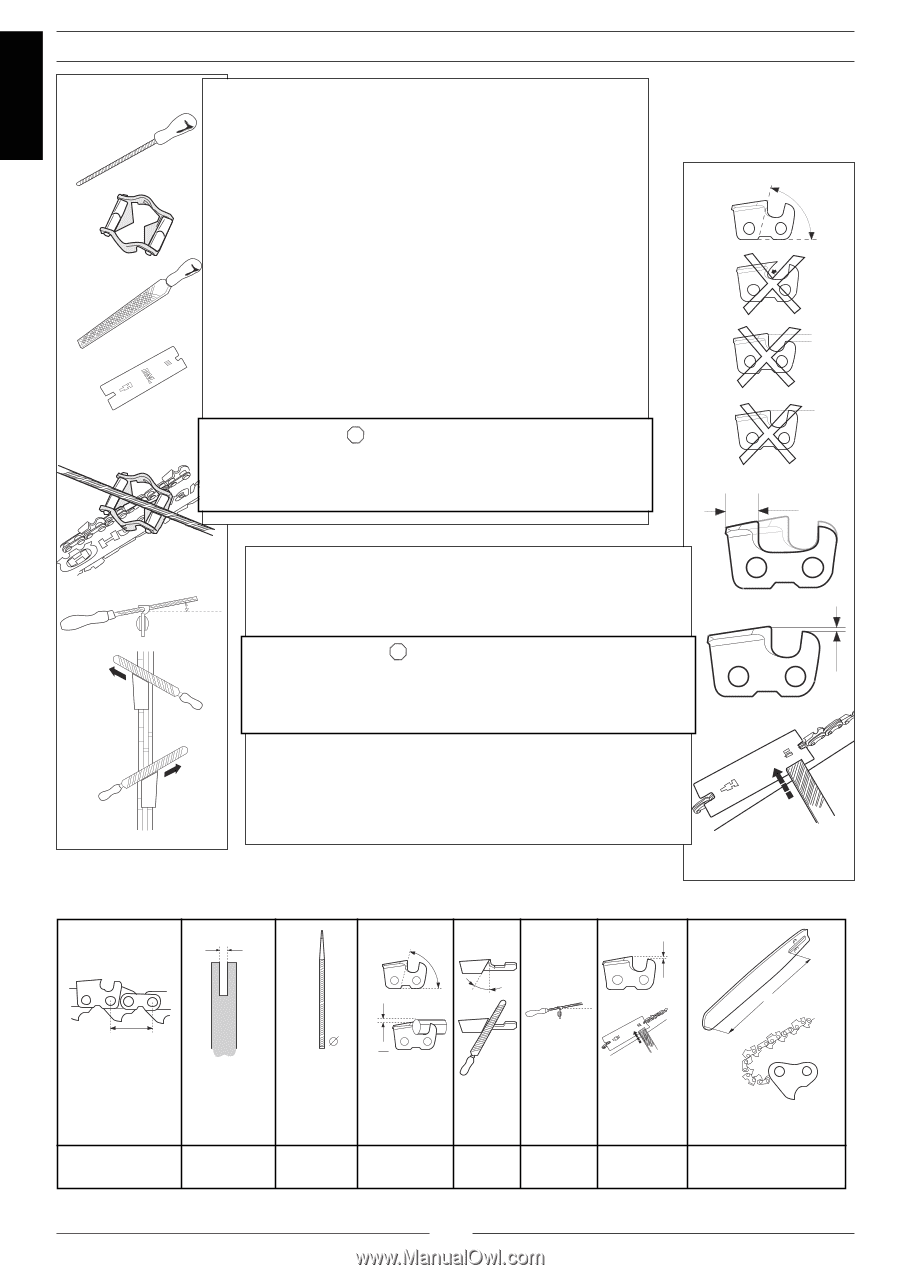

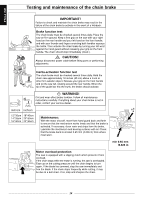

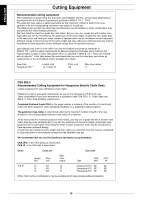

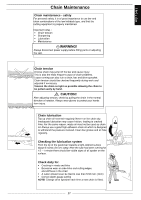

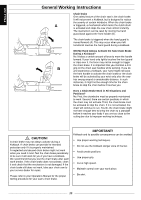

ENGLISH A B C D F Chain Maintenance Sharpening Never cut with a dull chain. A chain which does not cut unless you bear down hard is damaged, dull or incorrectly filed. To file the chain correctly, you need: round file (A), file gauge (B), flat file (C) and depth gauge tool (D). Best results are obtained by using the correct file size (see table) and a file gauge with a marked filing angle. NOTE! Check that the drive link does not show excessive play in the bar groove. This may affect the sharpening operation. Note that for some chains, the file is held level, while for others the file is held with the handle low at the angle indicated (E). Always file from the inside of the teeth and out (F). After filing one side, turn the saw and file the other side. To insure that the saw cuts straight, all teeth should be filed to the same length min. 0.15" (4mm). If the chain is sharpened regularly, only a few strokes of the file are needed on each tooth. To achieve maximum performance, each chain has a specific cutting angle, file size and depth. STOP WARNING! Filing too deep or using a file which is too small will make a chain dangerously aggressive. This means that the chain's tendency to kick back increases and the chain becomes dangerous to use. min 0.15 " min 4 mm Depth gauge E To ensure the best performance and longest service life of the chain, always keep the depth gauge at the prescribed length ( 0.025" / 0.65 mm ). .025 " / 0.65 mm STOP WARNING! An excessively low depth gauge makes the chain dangerously aggressive. This means that the chain's tendency to kick back increases and the chain becomes more dangerous to use. Depth gauges are checked using a depth gauge tool (for specification, see table). NOTE! The chain should be sharpened before depth gauges are checked. Adjustment of the depth gauge is done with a flat file. Round off the corner of the depth gauge afterwards. Approved bar / chain combinations L 1 5 inch inch/mm inch/mm ° ° H37 3/8" 0.050/1.3 5/32"/4.0 85° 30° 18 ° inch/mm inch/cm/dl 0° 0.025/0.65 12/30/45 14/35/52 16/40/56