Husqvarna 572 XP G Owner Manual - Page 22

Maintenance and checks of the safety, devices on the product

|

View all Husqvarna 572 XP G manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 22 highlights

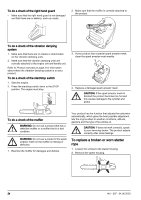

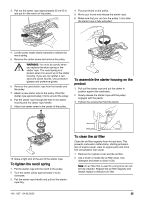

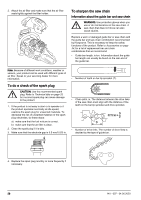

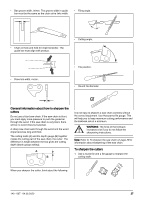

Daily maintenance Weekly maintenance Turn the guide bar, do a check of the lubrication hole and clean the groove in the guide bar. Refer to To do a check of the guide bar on page 30. Clean the carburetor area. Make sure that the guide bar and saw chain are getting sufficient oil. Clean or replace the air filter. Refer to To clean the air filter on page 25. Do a check of the saw chain. Refer to Clean between the cylinder fins. To examine the cutting equipment on page 30. Sharpen the saw chain and do a check of its tension. Refer to To sharpen the saw chain on page 26. Do a check of the chain drive sprocket. Refer to To do a check of the rim sprocket on page 29. Clean the air intake on the starter. Make sure that nuts and screws are tightened. Do a check of the stop switch. Refer to To do a check of the start/stop switch on page 24. Make sure that these are no fuel leaks from the engine, tank or fuel lines. Make sure that the saw chain does not rotate when the engine is at idle speed. Make sure that there is no damage on the right hand guard. Make sure that the muffler is correctly attached, has no damages and that no parts of the muffler are missing. Monthly maintenance Do a check of all cables and connections. Empty the fuel tank. Empty the oil tank. Maintenance and checks of the safety devices on the product To do a check of the brake band 1. Use a brush to remove wood dust, resin and dirt from the chain brake and clutch drum. Dirt and wear can decrease the function of the brake. 2. Do a check of the brake band. The brake band must be at a minimum of 0.6 mm/0.024 in thick at its thinnest point. To do a check of the front hand guard and the chain brake activation 1. Make sure that the front hand guard is not damaged and that there are no defects, such as cracks. 22 140 - 007 - 04.06.2020