Husqvarna 572 XP G Owner Manual - Page 29

To do a check of the saw chain, lubrication, To do a check of the rim sprocket, To lubricate

|

View all Husqvarna 572 XP G manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 29 highlights

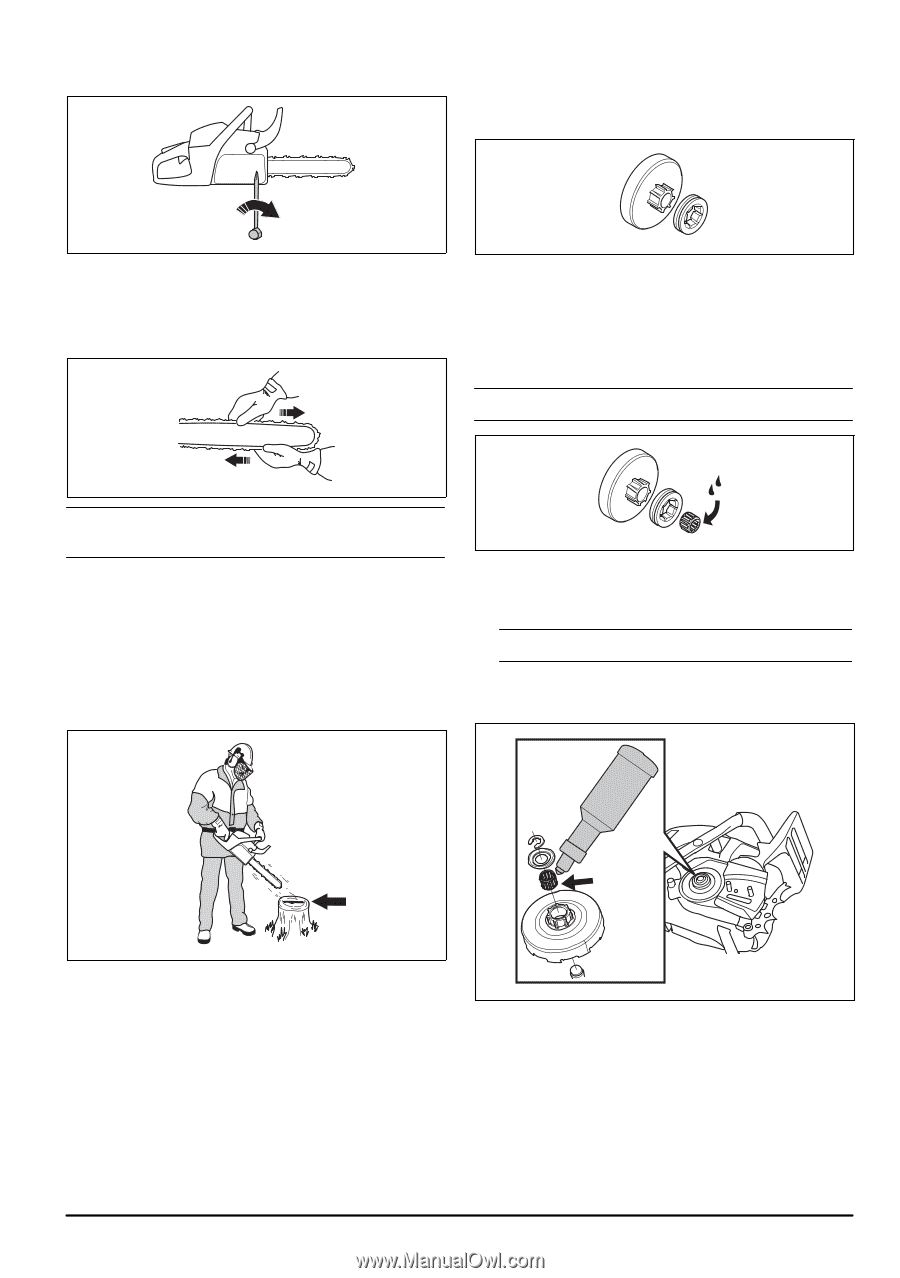

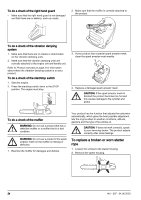

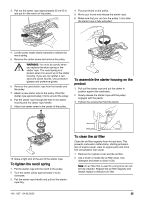

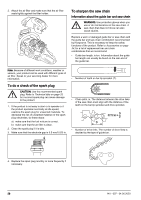

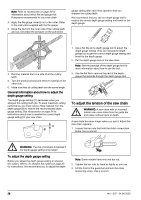

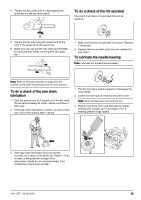

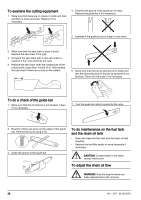

4. Tighten the saw chain until it is tight against the guide bar but still can move easily. To do a check of the rim sprocket The clutch drum has a rim sprocket that can be replaced. 5. Tighten the bar nuts using the wrench and lift the front of the guide bar at the same time. 6. Make sure you can pull the saw chain around freely by hand and that it does not hang from the guide bar. 1. Make sure that the rim sprocket is not worn. Replace if necessary. 2. Replace the rim sprocket each time you replace the saw chain. To lubricate the needle bearing Note: Lubricate the needle bearing weekly. Note: Refer to Product overview on page 2 for the position of the chain tensioning screw on your product. To do a check of the saw chain lubrication 1. Start the product and let it operate at ¾ throttle. Hold the bar approximately 20 cm/8 in above a surface of light color. 2. If the saw chain lubrication is correct, you see a clear line of oil on the surface after 1 minute. 1. Pull the front hand guard rearward to disengage the chain brake. 2. Loosen the bar nuts and remove the clutch cover. Note: Some models have only one bar nut. 3. Remove the clutch drum and lubricate the needle bearing with a grease gun. Use engine oil or a bearing grease of high quality. 3. If the saw chain lubrication does not operate correctly, do a check of the guide bar. Refer to To do a check of the guide bar on page 30 for instructions. Speak to your servicing dealer if the maintenance steps does not help. 140 - 007 - 04.06.2020 29