LG DLG2532W Owners Manual - Page 18

L.P. Liquefied - gas dryer

|

View all LG DLG2532W manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 18 highlights

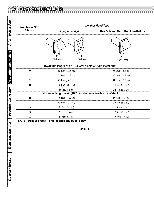

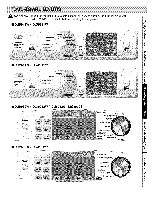

Gas Dryers N{)TE : The gas s_rvice to a gas d_er must conform with the l{_al codes and ordinances or, in the absence of h_al codes and ordinances, with the latest edition of the National Fuel Gas Code ANSI Z223.1!NFPA 54 or the CAN/CGA-B149, National Gas Ins_llation C_e. L.P (Liquefied Petroleum) Gas, 2,500 Bm/fl :_(93.1 MJ/m_), service musi _ st_pplied at 8M 3 irL water cohnnn pressure. [11[ NOTE : DO NOT connect the dryer tu L.P. Gas gvOl Service without converting the gas valve. LP. gas conversion: - Conversion must _e made by a qualified technician. See gas valve burner base for gas conversion kit part nuul_& Ill NOTE : When connecting to a gas line, an cquipment shutoff valve must be installed within 6 feet (1.8m) of the dryer. An 1/8 in. N.P.T. pipe plug must installt_'l as shown. Refer to Fig.1 Supply line requirements: Provide a rigid gas supply line to the dryer I{matiorL - An individual manual shutnff valve nmst be installed within 1.8m (6 feet) of me drycr in accordance with _le Natiorml l:uel Gas Code ANSI Z223.1". When a rigid pit_e is used it should be 1/2 inch IPS. When acccplable m lhe gas supplier and l(mal codes, 318o inch approved tubing m W b_,_u,ved for leuglhs under 6.1 m (20 l_2e{).For lcugths over 6.hn (20 lee0, larger tubing sh{mld b_ used. t}it'_e2jointcoinpom_ds resislani to the action of L.P. gas must _ used. To r_uce the risk of gas leaks, fire or • The dryer must be connected to the type of gas as shown on the nameplate Iocat_ in the door recess. • Use a new flexible stainless steel connector. • Use pipe joint compound insoluble in L.P. (Liquefied Petroleum) Gas, or Teflon tape, on all pipe threads. • Purge air and sediment from gas supply line before connecting it to the dryer. Before tightening the connection, purge remaining air from gas line to dryer until odor of gas is detected. This step is required to prevent a gas valve contamination. • Do not use an open flame to check for gas leaks. Use a non-corrosive leak detection fluid. Any dis-assembly requiring the u_ of tools must be performed by an authorized qualified service _rson, 18