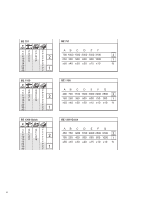

Metabo BE 1100 Operating Instructions 2 - Page 9

Original instructions - drill

|

View all Metabo BE 1100 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 9 highlights

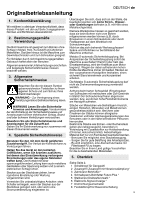

Original instructions ENGLISH en 1. Declaration of Conformity We, being solely responsible, hereby declare that this product conforms to the standards and directives specified on page 3. 2. Specified Use The drill is suitable for non-impact drilling into metal, wood, plastic and similar materials. It is also suitable for thread tapping and screwdriving. The user bears sole responsibility for any damage caused by improper use. Generally accepted accident prevention regulations and the enclosed safety information must be observed. 3. General Safety Instructions For your own protection and for the protection of your electrical tool, pay attention to all parts of the text that are marked with this symbol! WARNING - Reading the operating instructions will reduce the risk of injury. WARNING Read all safety warnings and instructions. Failure to follow all safety warnings and instructions may result in electric shock, fire and/or serious injury. Keep all safety instructions and information for future reference. Pass on your electrical tool only together with these documents. Keep hands away from the rotating tool! Remove chips and similar material only when the machine is not in operation. Metabo S-automatic safety clutch. When the safety clutch responds, switch off the machine immediately! If the tool jams or catches, the power supply to the motor is restricted. Due to the strong force which can arise, always hold the machine with both hands using the handles provided, stand securely and concentrate. The Metabo S-automatic safety clutch must not be used for torque control. Caution must be exercised when driving screws into hard materials (driving screws with metric or imperial threads into steel)! The screw head may break, or a high reverse torque may build up on the handle. Dust from material such as paint containing lead, some wood species, minerals and metal may be harmful. Contact with or inhalation of the dust may cause allergic reactions and/or respiratory diseases to the operator or bystanders. Certain kinds of dust are classified as carcinogenic such as oak and beech dust especially in conjunction with additives for wood conditioning (chromate, wood preservative). Material containing asbestos must only be treated by specialists. - Where the use of a dust extraction device is possible it shall be used. - The work place must be well ventilated. - The use of a dust mask of filter class P2 is recommended. Follow national requirements for the materials you want to work with. 5. Overview 4. Special Safety Instructions Use the additional handle supplied with the tool. Loss of control can cause personal injury. Hold the power tool by insulated gripping surfaces, when performing an operation where the cutting accessory may contact hidden wiring or its own cord. Cutting accessory contacting a "live" wire may make exposed metal parts of the power tool "live" and could give the operator an electric shock. Pull the plug out of the plug socket before any adjustments or servicing are performed. Avoid inadvertent starts by always unlocking the switch when the plug is removed from the mains socket or in case of a power cut. See page 2. 1 Thumbwheel for gear selection 2 Additional handle / Additional handle with vibration damping * 3 Geared chuck* 4 Futuro Plus keyless chuck * 5 Speed preselection setting wheel* 6 Electronic signal indicator* 7 Rotation selector switch 8 Locking button for continuous activation 9 Trigger switch * depending on equipment 6. Initial Operation Ensure that the spot where you wish to work is free of power cables, gas lines or water pipes (e.g. using a metal detector). Before plugging in, check that the rated mains voltage and mains frequency, as stated on the rating label, match with your power supply. Smaller workpieces must be secured such that they are not carried along with the drill bit when drilling (e.g. by clamping in a vice or on a work bench with screw clamps). To ensure that the drill chuck is securely fitted: After initial drilling (clockwise), use a screwdriver to firmly tighten the safety screw inside the drill chuck (if applicable / model-specific). 9