Pfaff powerquilter 16.0 Manual - Page 17

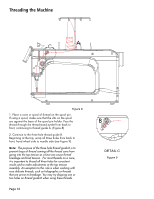

Detail D, Scale 1 : 2

|

View all Pfaff powerquilter 16.0 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 17 highlights

C ED F DETAIL D SCALE 1 : 2 Figure 10 3. Thread continues through thread guide C, and then down to the tension assembly (see Figure 10). Note: It is important that the thread is "flossed" up between the two tension discs. If the thread is not firmly in place between the two tension discs, the thread rests on the outside of the tension discs (without tension) and D C looping on fabric or thread nests may occur. 4. Once the thread is in place, be sure that the thread catches on the take-up spring and then pull it down under the stirrup (thread guide D). 5. Bring the thread back up through the take-up lever from back to front, and then down through thread guide E. Pull the thread at the take-up lever to ensure that it is properly flossed between the tension disks. If it is properly flossed in the tension disks you should feel some resistance as you pull the thread. If it is not, then the thread will pull freely. 6. Pull the thread down to the needle thread guide and thread through the hole (thread guide F). 7. Make sure the thread is following the groove down the front of the needle and threads from front to back. Be careful that the thread does not twist around the needle. IMPORTANT NOTE: The powerquilter™ 16.0 quilting machine does not have a presser foot lever or top tension release like a home sewing machine. On a home sewing machine the top tension is released when the presser foot is raised, allowing the thread to come freely out of the machine. When a home machine is threaded, the presser foot is raised and the tension discs are released and open for the thread to easily fall between the tension discs. This is not the case with the powerquilter™ 16.0 quilting machine where the top tension is always tight and the tension discs are never open. Therefore, the thread must be pulled up or "flossed" between the tension discs or it will stay outside the discs and float without tension, causing serious stitch problems and/ or thread nests. It is also possible to bend the needle while it is threaded if care is not taken while moving the machine around the quilt because the top tension is never released. DETAIL C SCALE 1 : 2 Page 17