Pyle PKBRKTL200 Instruction Manual - Page 6

Using The Home Beer Brewing Machine, Understanding The Home Beer Brewing Machine Controller

|

View all Pyle PKBRKTL200 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 6 highlights

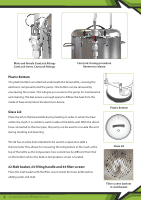

Switch the brew program selector to "II" and press "RUN" button on the brew controller. The display light will now illuminate. This will initiate heating of the water to 100°C or 212°F. Wait until the water is boiling. Then open the riser pipe valve before switching on the pump. Let the pump run for about 10 minutes in order to clean the equipment pipes and pump. • While the pump is running you should check for leakages around ttings and tighten the ttings if required. USING THE HOME BEER BREWING MACHINE This chapter will explain brewing in general, and how to use the brew controller and the program selector switch during brewing. UNDERSTANDING THE HOME BEER BREWING MACHINE CONTROLLER: The Home Beer Brewing Machine has an easy to use built-in controller that has been designed to support the three phases of brewing described above. Each phase is completed by basically heating up and maintaining temperatures, where each phase has a di erent function in the beer brewing process. The phases are displayed as HEAT (preheating), MASH (mashing), LAUTER (lauthering) and BOIL (boiling) in the brew controller display. Each phase has three parameters that can be changed: a. Heating power, in percent % b. Target temperature (°C and °F) c. Time (M) The brew controller has been pre-programmed with parameter values that is suitable for brewing using a single step mashing at 65°C or 149°F, with the malt basket equipment setup. Each of the three phases have been set up with a duration of 60 minutes. This will be suitable for most beer recipes where modern, well modi ed malts are used. 6 www.NutrichefKitchen.com