Ridgid GP80145SW Operation Manual - Page 16

Troubleshooting

|

View all Ridgid GP80145SW manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 16 highlights

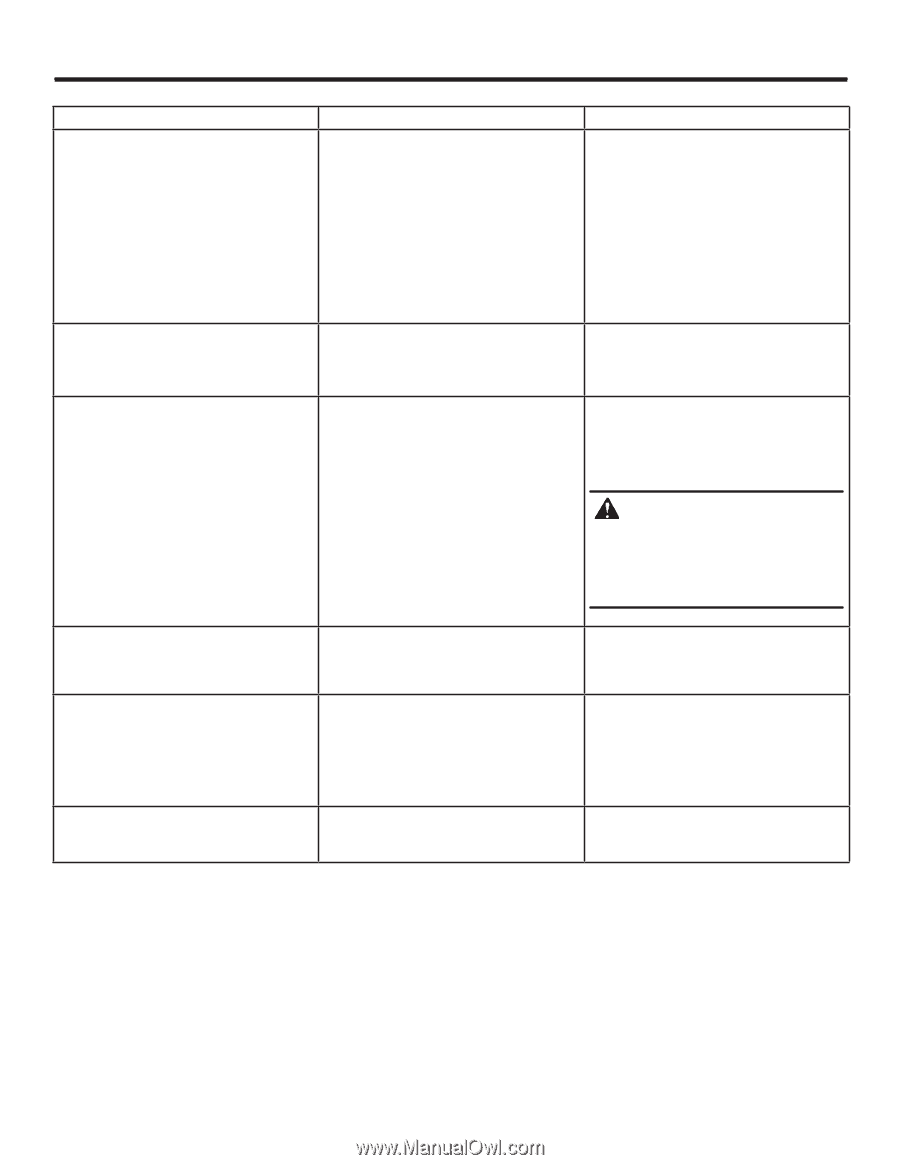

TROUBLESHOOTING PROBLEM Engine will not start. CAUSE On/stop switch is in off position. No fuel. Fuel valve is off. Spark plug faulty, fouled, or improperly gapped. Choke lever is in RUN position. Tank is full of air. SOLUTION Turn the on/stop switch to ON. Fill fuel tank. Turn fuel valve on. Replace spark plug. Move choke lever to START position. Compressor will turn on when tank pressure drops to cut-in pressure. Engine lacks power. Fuel element clogged. Defective pressure unloader. Check air filter element. Clean or replace as needed. Take compressor to service center. Air tank pressure drops when compres- Loose connections (fittings, tubing, etc.). Check all connections with soap and sor shuts off. water solution and tighten. Loose drain valve. Tighten drain valve. Pressure unloader leaking. Take compressor to service center. DANGER: Do not disassemble pressure unloader, tank drain valves or safety relief valve with air in tank - bleed tanks. Excessive moisture in discharge air. Excessive water in air tanks. High humidity. Compressor runs continuously. Defective pressure unloader. Excessive air usage. Air output lower than normal. Piston rings are worn. Broken inlet valves. Connections leaking. Drain tanks. Move to area of less humidity; use air line filter. Take compressor to service center. Decrease air usage; compressor not large enough for tool's requirement. Replace piston rings; Call customer service for assistance. Take compressor to service center. Tighten connections. 16 - English