Seagate ST800FM0022 Pulsar.2 SAS Product Manual - Page 43

Defect And Error Management

|

View all Seagate ST800FM0022 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 43 highlights

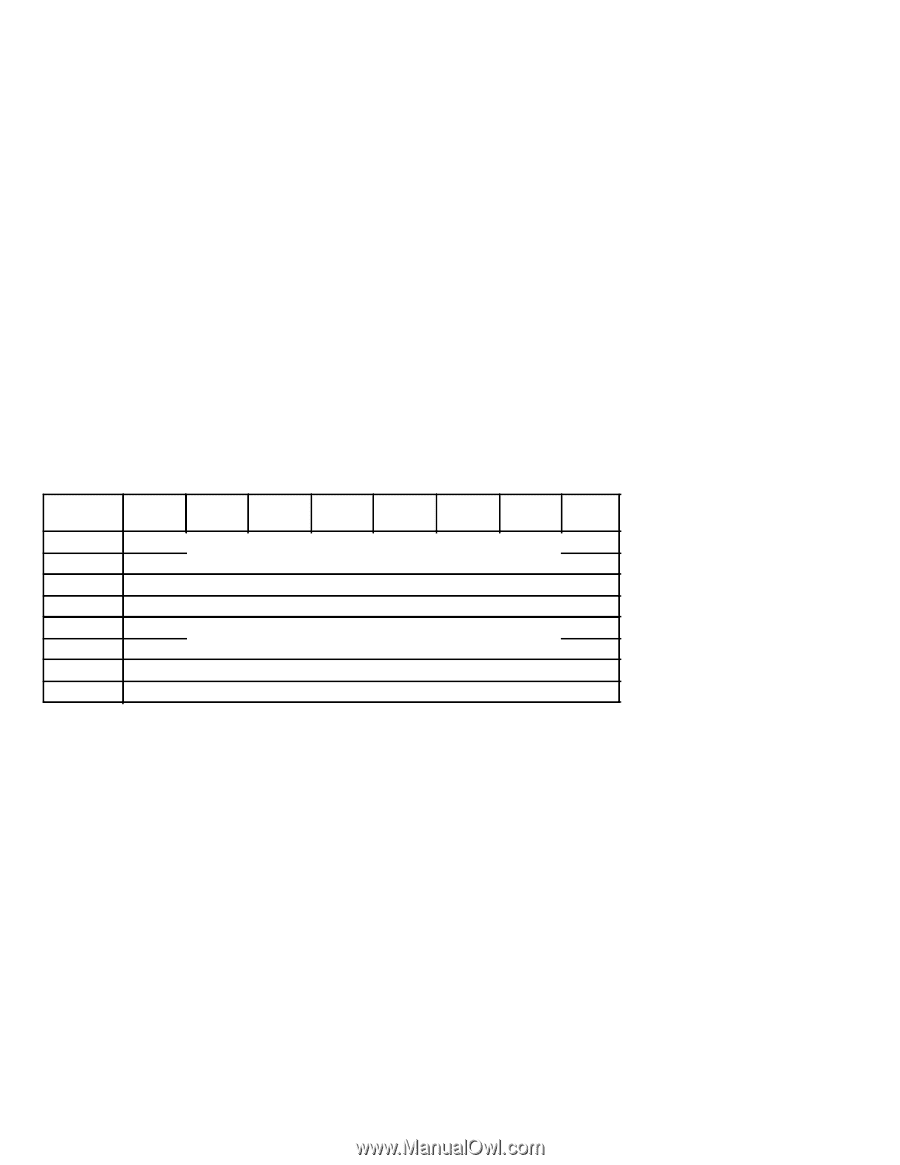

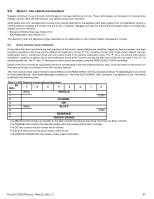

9.0 DEFECT AND ERROR MANAGEMENT Seagate continues to use innovative technologies to manage defects and errors. These technologies are designed to increase data integrity, perform drive self-maintenance, and validate proper drive operation. SCSI defect and error management involves drive internal defect/error management and SAS system error considerations (errors in communications between the initiator and the drive). In addition, Seagate provides the following technologies used to increase data integrity and drive reliability: • Background Media Scan (see Section 9.4) • Auto-Reallocation (see Section 9.5) The read error rates and specified storage capacities are not dependent on host (initiator) defect management routines. 9.1 DRIVE INTERNAL DEFECTS/ERRORS During the initial drive manufacturing test operation at the factory, media defects are identified, tagged as being unusable, and their locations recorded on the drive primary defects list (referred to as the "P' list). At factory format time, these known defects are also deallocated, that is, marked as retired and the location listed in the defects reallocation table. The "P" list is not altered after factory formatting. Locations of defects found and reallocated during error recovery procedures after drive shipment are listed in the "G" list (defects growth list). The "P" and "G" lists may be referenced by the initiator using the READ DEFECT DATA command. Details of the SCSI commands supported by the drive are described in the SAS Interface Manual. Also, more information on the drive Error Recovery philosophy is presented in the SAS Interface Manual. The drive uses a vendor unique format to report defects via the READ DEFECT DATA command pending T10 standardization of a format for Solid State Devices. This format defect type is defined as 110b in the SCSI FORMAT UNIT command. The definition of the 110b format is defined in the following table. Table 13 SSD Physical format address descriptor Bit Byte 7 6 5 4 3 2 1 0 0 (MSB) MEDIA ID 1 (LSB) 2 CHANNEL 3 DIE 4 (MSB) BLOCK 5 (LSB) 6 RESERVED 7 VENDOR UNIQUE The MEDIA ID field contains an identifier for the flash controller for devices that utilize more than one flash controller. The CHANNEL field contains the channel number within the corresponding Flash Controller. The DIE field contains the die number within channel. The BLOCK field contains the block number within the die. The VENDOR UNIQUE field may contain vendor unique information. PULSAR.2 SAS PRODUCT MANUAL, REV. C 37