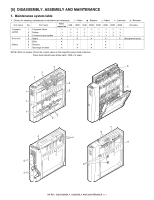

Sharp AR-RB1 Service Manual - Page 9

Initial operation, Straight delivery operation

|

View all Sharp AR-RB1 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 9 highlights

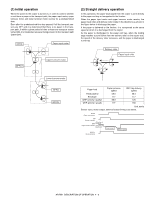

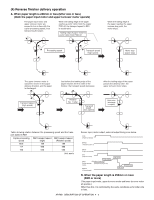

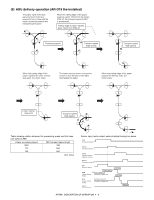

(1) Initial operation When the power to the copier is turned on, in order to confirm whether or not there is paper in the transport path, the paper input motor, upper turnover motor and lower turnover motor revolve for a predetermined time. Even after the predetermined time has passed, if all the transport sensors are OFF and it is determined that there is no paper in the transport path, if within a given period of time at least one transport sensor turned ON, it is interpreted as paper being present in the transport path (paper jam). BPOD Paper input motor BPPD1 Upper turnover motor (2) Straight delivery operation In this operation, the paper discharged from the copier is sent directly to the paper exit tray or transported to the finisher. When the paper input motor and upper turnover motor revolve, the paper input roller and delivery roller rotate in the directions as shown in the figure below to discharge the paper. If the paper is delivered to the finisher, it is transported at the same speed at which it is discharged from the copier. As the paper is discharged to the paper exit tray, when the trailing edge reaches a point 50mm from the delivery roller on the copier side, the speed of the delivery roller increases, and the paper is discharged to the tray. Delivery roller Paper input roller Lower turnover motor BPRD BPPD2 Paper kind Thick paper 2 Envelope OHP (priority: quality) OHP (priority: speed) Copier process speed 58.5 117 58.5 117 RB1 tray delivery speed 58.5 117 120 160 Unit: mm/s Sensor input, motor output, solenoid output timing is as below. BPOD (Paper exit sensor) BIM (Paper-in motor) (Direction of BRM paper-in) (Upper reverse motor) (Direction of paper-out) Process speed BGSOL (Gate solenoid) Delivery speed AR-RB1 DESCRIPTION OF OPERATION 4 - 2