Sharp LC-60LE810UN Service Manual - Page 43

Microcomputer software writing, Signal adjustment - backlight

|

UPC - 074000372580

View all Sharp LC-60LE810UN manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 43 highlights

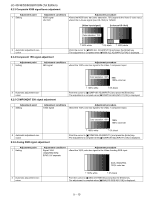

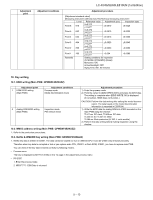

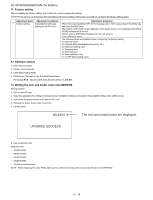

7. Microcomputer software writing LC-40/46/52/60LE810UN (1st Edition) 7.1. Main microcomputer/monitor microcomputer software writing (Main PWB: QPWBXF452WJZZ) Adjustment item Adjustment conditions 1 Main microcomputer/moni- Checker process tor microcomputer software writing File version check USB memory check Adjustment procedure 1. Connect the specified writing jig to SC8452 (TL8461-8475) via the checker. 2. Connect the USB memory to J3301 (TL3309-3312) or J3302 (TL3332-3335) via the checker. 3. Apply the specified voltage to the PWB and perform boot from the jig. 4. Send the software writing start command via RS232C. 5. Send the writing status check command and confirm the response of OK. Then turn off the power. CAUTION: When the USB memory is not inserted or reading error occurs, nothing is written. 7.2. Model/inch discrimination writing (Main PWB: QPWBXF452WJZZ) • Refer to the production precautions. 8. Signal adjustment 8.1. LCD section adjustment [LCD module adjustment] Adjustment item 1 Opposite bias adjustment (LCD module adjustment item) Adjustment conditions Adjustment in the center position of the panel Adjustment procedure 1. Enter the process mode using the process adjustment remote control. 2. Select [VCOM ADJ] using the Channel / keys on the remote control. 3. Press the Enter key to check that the pattern for adjustment is displayed. 4. Make adjustment so that the flicker located in the center of the screen is minimized using the Volume +/- keys on the remote control. 5. If the optimum condition is obtained in step 4, press the Enter key to turn off the pattern. CAUTION: * Make adjustment with no ANT signal (since the brightness is changed by the active backlight). [Adjustment position] 1/4 3/4 1/2 1/2 8.2. Image adjustment 8.2.1 Device check Before adjustment, check that the adjustment jig and signal source are set for Sharp LCD US. Signal generator level adjustment check (Adjust to the standard value level.) •Composite signal: •15K component signal: •33K component signal: •Analog RGB: Y level: PB/PR level: Y level: PB/PR level: RGB level: 0.714Vp-p ± 0.02Vp-p (Pedestal to white) 0.714Vp-p± 0.02Vp-p (Pedestal to white) 0.7Vp-p ± 0.02Vp-p 0.7Vp-p ± 0.02Vp-p (Pedestal to white) 0.7Vp-p ± 0.02Vp-p 0.7Vp-p ± 0.02Vp-p (Pedestal to white) 8.2.2 Process mode Adjustment point Process mode Adjustment conditions Adjustment procedure Enter the process adjustment mode using the process adjustment remote control. 5 - 9