Troy-Bilt TB30 Operation Manual - Page 22

Adjustments, Cleaning the Engine And Deck

|

View all Troy-Bilt TB30 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 22 highlights

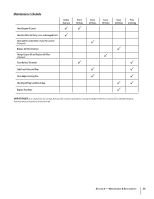

Steering Rack & Pinion Once per season, or every 25 hours of operation, it will be necessary to lubricate the steering rack and pinion gear located under the front of the unit. Using standard automotive grease, apply grease to the front side and rear side of the steering rack, as indicated in Figure 6-2. Figure 6-2 Cleaning the Engine And Deck If the engine has been running, allow it to cool for at least half an hour before cleaning. Periodically remove dirt build-up from engine. Clean cooling fins every 25 hours. Clean with a brush or compressed air. IMPORTANT: Do not spray engine with water to clean because water could contaminate fuel. Using a garden hose or pressure washing equipment can also force water into the air cleaner or muffler opening. Water in the air cleaner will soak the paper element, and water that passes through the element or muffler can enter the cylinder, causing damage. Any fuel or oil spilled on the machine should be wiped off promptly. Do NOT allow debris to accumulate around the cooling fins of the engine or on any other part of the machine. IMPORTANT: The use of a pressure washer to clean your tractor is NOT recommended. It may cause damage to electrical components, spindles, pulleys, bearings or the engine. WARNING! Accumulation of debris around muffler could cause a fire. Inspect and clean before every use. Battery The battery is sealed and is maintenance-free. Acid levels cannot be checked. • Always keep the battery cables and terminals clean and free of corrosive build-up. • After cleaning the battery and terminals, apply a light coat of petroleum jelly or grease to both terminals. • Always keep the rubber boot positioned over the positive terminal to prevent shorting. IMPORTANT: If removing the battery for any reason, disconnect the NEGATIVE (Black) wire from it's terminal first, followed by the POSITIVE (Red) wire. When re-installing the battery, always connect the POSITIVE (Red) wire its terminal first, followed by the NEGATIVE (Black) wire. Be certain that the wires are connected to the correct terminals; reversing them could change the polarity and result in damage to your engine's alternating system. Cleaning Battery Clean the battery by removing it from the tractor and washing with a baking soda and water solution. If necessary, scrape the battery terminals with a wire brush to remove deposits. Coat terminals and exposed wiring with grease or petroleum jelly to prevent corrosion. Adjustments WARNING: Never attempt to make any adjustments while the engine is running, except where specified in the operator's manual. Steering Adjustment If the tractor turns tighter in one direction than the other, or if the front tie rod is being replaced due to damage or wear, the steering will need to be adjusted. To Adjust the toe in/out of the front wheels: 1. Remove the bow-tie clip securing the tie-rod ferrule to the right front axle assembly, and drop the tie-rod down to adjust. See Figure 6-3. Muffler WARNING! Temperature of muffler and nearby engine areas may exceed 150˚ F (65˚C). Avoid contact with these areas. Inspect muffler periodically, and replace if necessary. Replacement parts for the muffler must be the same and installed in the same position as the original parts. 22 Section 6- Maintenance & Adjustments Figure 6-3