Ariens Pro Track 28 Owners Manual - Page 22

GENERAL LUBRICATION, Auger Shaft, Clean Battery 926104

|

View all Ariens Pro Track 28 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 22 highlights

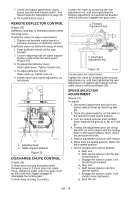

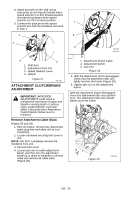

To ensure adequate lubricant level: 1. Remove filler plug. Lubricant must be at least up to bottom of lubricant filler hole with unit resting on a level-surface. 2. Add lubricant if required. Allow oil to drain to level of plug and replace plug. IMPORTANT: Use only Ariens L-3 synthetic severe duty gear lube (Part Number 00068800). NOTE: Gearcase filler plug may require an application of Loc-Tite® 565 thread sealant with repeated servicing. If Loc-Tite® 565 is not available, use PTFE pipe sealing tape on the filler plug. 1 2 Oil Grease 1. Auger Gearcase 2. Oil Fill and Drain Plug Figure 17 OS7133 GENERAL LUBRICATION IMPORTANT: Wipe each fitting clean before and after lubrication. Do not wipe gearcase filler plug; wiping the gearcase filler plug may remove thread sealant and cause leaks. IMPORTANT: DO NOT allow grease or oil to get on friction disc, friction plate or belts. NOTE: Apply Ariens Hi-Temp Grease or equivalent to the lubrication fittings. See SERVICE PARTS on page 33. Sno-Thro should be lubricated (Figure 18) at beginning of season or every 25 operating hours. Auger Shaft NOTE: To grease auger shaft, remove shear bolt nuts, and shear bolts. Apply grease at the grease zerks and then turn the auger shaft. Replace shear bolts per instructions in Shear Bolts on page 24. Figure 18 Clean Battery (926104, 105) WARNING: AVOID INJURY. Read and understand the entire Safety section before proceeding. IMPORTANT: Battery is maintenance-free. Do not tamper with or attempt to open battery. See SERVICE AND ADJUSTMENTS on page 23 for charging procedures. Terminals Keep battery and its terminals clean. IMPORTANT: Remove battery from unit before cleaning. Remove corrosion from battery terminals and cable connections with a wire brush, then wash with a weak baking soda solution. After cleaning, apply a thin coat of grease or petroleum jelly to terminals and cable ends to retard corrosion. GB - 22