Canon PIXMA iP4200 Service Manual - Page 17

Repair - printer head repair

|

View all Canon PIXMA iP4200 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 17 highlights

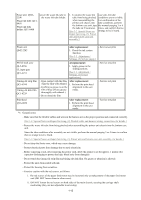

3. REPAIR 3-1. Notes on Service Part Replacement (and Disassembling / Reassembling) Service part Logic board ass'y QM2-2670 Ink absorber kit QY5-0146 Carriage unit QM2-2207 Paper feed motor QK1-1502 Platen unit: QM22202 Notes on replacement*1 Adjustment / settings Operation check - Before removal of the logic After replacement: board ass'y, remove the power cord, and allow for approx. 1 minute (for discharge of capacitor's accumulated charges), to prevent damages to the 1. Initialize the EEPROM. 2. Reset the waste ink counter. 3. Set the destination in the EEPROM. logic board ass'y. 4. Correct the CD / DVD - Before replacement, check the waste ink amount (by and automatic print head alignment sensors. service test print or 5. Check the ink system EEPROM information function. print). If the waste ink [See 3-3. Adjustment / amount is 7% or more, also Settings, (5) Service mode, replace the ink absorber kit for details of 1 to 5] when replacing the logic board ass'y. 6. Perform the print head alignment in the user [See 3-3. Adjustment / mode. Settings, (5) Service mode, for details.] - EEPROM information print - Service test print - Printing via USB connection - Direct printing from a digital camera After replacement: 1. Reset the waste ink counter. [See 3.3. Adjustment / Settings, (5) Service mode.] - Service test print - EEPROM information print At replacement: 1. Apply grease to the sliding portions. [See 3-3. Adjustment / Settings, (2) Grease application.] After replacement: 1. Correct the CD / DVD and automatic print head alignment sensors. [See 3.3. Adjustment / Settings, (5) Service mode.] 2. Check the ink system function. [See 3.3. Adjustment / Settings, (5) Service mode.] - Service test print (Confirm CD / DVD and automatic print head alignment sensor correction, and ink system function.) 3. Perform the print head alignment in the user mode. - The red screws securing the At replacement: paper feed motor are 1. Adjust the paper feed allowed to be loosened. motor. (DO NOT loosen any other red screws.) [See 3-3. Adjustment / Settings, (1) Paper feed motor adjustment.] - By attaching the tape at the At replacement: specified 2 locations, After the printer unit is assembled in the bottom 1-12