Canon PIXMA iP4200 Service Manual - Page 6

Maintenance - reset

|

View all Canon PIXMA iP4200 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 6 highlights

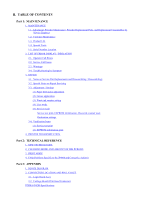

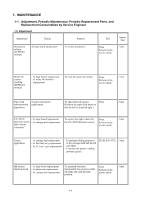

1. MAINTENANCE 1-1. Adjustment, Periodic Maintenance, Periodic Replacement Parts, and Replacement Consumables by Service Engineer (1) Adjustment Adjustment Timing Purpose Tool Approx. time Destination settings (EEPROM settings) At logic board replacement To set the destination. None. Perform in the service mode. 1 min. Waste ink counter resetting (EEPROM settings) - At logic board replacement - At waste ink absorber replacement To reset the waste ink counter. None. Perform in the service mode. 1 min. Paper feed motor position adjustment At paper feed motor replacement To adjust the belt tension. None. (Position the paper feed motor so that the belt is stretched tight.) 5 min. CD / DVD - At logic board replacement detection sensor - At carriage unit replacement light volume correction*1 To correct the light volume for the CD / DVD detection sensor. None. Perform in the service mode. 2 min. Grease application - At carriage unit replacement - At PR shaft ass'y replacement - At CL base / gear replacement - To maintain sliding properties of the carriage shaft and the lift cam shaft. - To protect the printer's sliding portions (gears). FLOIL KG-107A 1 min. Ink system function check - At logic board replacement - At platen unit replacement - At carriage unit replacement To maintain detection functionality for presence of the ink tanks and each ink tank position. None. Perform in the service mode. 1 min. 1-1