Ryobi RY10518 Operator's Manual - Page 33

Cleaning The Air Filter

|

View all Ryobi RY10518 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 33 highlights

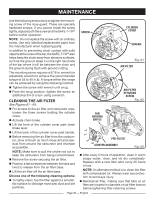

MAINTENANCE Use the following instructions to tighten the mounting screw of the nose guard. These are specially hardened screws. If you cannot install the screw tightly, replace both the screw and the SAFE-T-TIP® before further operation. SCREW CYLINDER COVER NOTE: Do not replace the screw with an ordinary screw. Use only identical replacement parts from the manufacturer when replacing parts. SCREWS In addition to preventing chain contact with solid objects at the nose of the bar, the SAFE-T-TIP® also helps keep the chain away from abrasive surfaces, such as the ground. Keep it on the right hand side of the bar where it will be between the chain and the ground during flush with ground cutting. Fig. 61 AIR FILTER The mounting screw requires a 5/16 in. wrench (or adjustable wrench) to achieve the recommended torque of 35 to 45 in.lb. A torque within this range can be achieved by using the following method. n Tighten the screw with wrench until snug. n From the snug position, tighten the screw an additional 3/4 of a turn using a wrench. CLEANING THE AIR FILTER See Figures 61 - 64. n For access to the air filter and carburetor area, loosen the three screws holding the cylinder cover. n Activate chain brake. n Lift the front of the cylinder cover past chain brake lever. n Lift the back of the cylinder cover past handle. n Before removing the air filter from the carburetor, blow or brush as much loose dirt and sawdust from around the carburetor and chamber as possible. FAN HOUSING BAFFLE AIR FILTER RETAINING SCREW Fig. 62 PRE-FILTER STARTER ASSEMBLY Fig. 63 NOTE: Make sure to pull the choke rod out to keep the carburetor from being contaminated. n Remove the screw securing the air filter. n Position a flat screwdriver between the tabs and twist to release from the air filter base. n Lift the air filter off the air filter base. Choose one of the following cleaning options: n To lightly clean, tap the filter against a smooth, flat surface to dislodge most saw dust and dirt particles. n After every 5 hours of operation, clean in warm soapy water, rinse, and let dry completely. Replace with a new filter after every 25 hours of use. NOTE: An alternate method is to clean the filter with compressed air. Always wear eye protection to avoid eye injury. n Reinstall air filter, making sure that tabs on air filter are located in channels on air filter bottom before tightening filter retaining screws. Page 33 - English