Ryobi RY10518 Operator's Manual - Page 36

Spark Arrestor, Inspecting And Cleaning Chain, Brake, Warning, Storing The Product - model

|

View all Ryobi RY10518 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 36 highlights

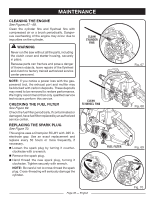

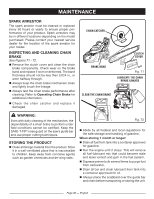

MAINTENANCE SPARK ARRESTOR The spark arrestor must be cleaned or replaced every 50 hours or yearly to ensure proper performance of your product. Spark arrestors may be in different locations depending on the model purchased. Please contact your nearest service dealer for the location of the spark arrestor for your model. INSPECTING AND CLEANING CHAIN BRAKE See Figures 71 - 72. n Remove the clutch cover and clean the chain brake components. Check wear on the brake band and replace if worn or deformed. The band thickness should not be less than 0.024 in., or worn halfway through. n Always keep the chain brake mechanism clean and lightly brush the linkage. n Always test the chain brake performance after cleaning. Refer to Operating Chain Brake for additional information. n Check the chain catcher and replace if damaged. CHAIN CATCHER BRAKE BAND CLUTCH COVER Fig. 71 LUBRICATE THE CHAIN BRAKE LINKAGE CLEAN THE CHAIN BRAKE WARNING: Even with daily cleaning of the mechanism, the dependability of a chain brake to perform under field conditions cannot be certified. Keep the SAFE-T-TIP® nose guard on the saw's guide bar and use proper cutting techniques. STORING THE PRODUCT n Clean all foreign material from the product. Store it in a well-ventilated place that is inaccessible to children. Keep away from corrosive agents such as garden chemicals and de-icing salts. Fig. 72 n Abide by all Federal and local regulations for the safe storage and handling of gasoline. When storing 1 month or longer: n Drain all fuel from tank into a container approved for gasoline. n Run the engine until it stops. This will remove all fuel-lubricant mix that could become stale and leave varnish and gum in the fuel system. n Squeeze primer bulb several times to purge fuel from carburetor. n Drain all bar and chain lubricant from tank into a container approved for oil. n Always place the scabbard over the guide bar and chain before transporting or storing the unit. Page 36 - English