Brother International Innov-is 85e Operation Manual - Page 142

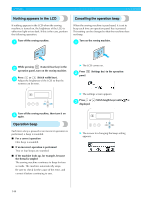

Nothing appears

|

View all Brother International Innov-is 85e manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 142 highlights

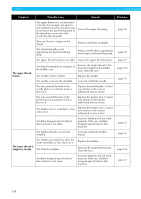

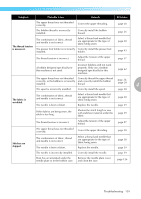

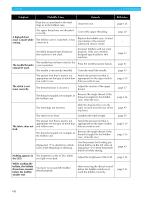

APPENDIX Symptom Probable Cause Remedy Dust has accumulated in the feed dogs or in the bobbin case. Clean the race. A high-pitched noise is made while sewing. The upper thread was not threaded correctly. The bobbin case is scratched, or has a burr on it. Correct the upper threading. Replace the bobbin case. Contact your dealer or the nearest authorized service center. A bobbin designed specifically for this machine is not used. Incorrect bobbins will not work properly. Only use a bobbin designed specifically for this machine. The needle threader cannot be used. The needle has not been raised to the correct position. The needle is incorrectly installed. Press the needle position button. Correctly install the needle. The presser foot that is used is not Attach the presser foot that is appropriate for the type of stitch that appropriate for the type of stitch you wish to sew. that you wish to sew. The stitch is not sewn correctly. The thread tension is incorrect. Adjust the tension of the upper thread. The thread is tangled, for example, in the bobbin case. Remove the tangle thread. If the thread is tangled in the bobbin case, clean the race. The feed dogs are lowered. Slide the drop feed lever to the right. (as seen from the rear of the machine) The stitch is too short. Lengthen the stitch length. The fabric does not feed. The presser foot that is used is not appropriate for the type of stitch that you wish to sew. The thread is tangled, for example, in the bobbin case. Attach the presser foot that is appropriate for the type of stitch that you wish to sew. Remove the tangle thread. If the thread is tangled in the bobbin case, clean the race. Zigzag foot "J" is slanted on a thick seam at the beginning of stitching. Use the presser foot locking pin (black button on the left side) on zigzag foot "J" to keep the presser foot level while sewing. Nothing appears in The brightness of the LCD is either the LCD. too light or too dark. Adjust the brightness of the LCD. While winding the bobbin, the bobbin thread was wound below the bobbin winder seat. You have not wound the bobbin thread properly. After removing the thread wound below the bobbin winder seat, wind the bobbin correctly. Reference page 126 page 28 - page 22 page 31 page 39 page 120 page 57 page 126 page 97 page 59 page 120 page 126 page 63 page 144 page 135 140