Canon BJC 6000 Service Manual - Page 90

Purge unit, 1.4 Paper feed unit

|

View all Canon BJC 6000 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 90 highlights

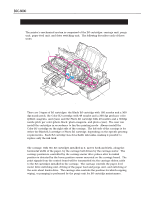

Part 4: Technical Reference BJC-6000 3.1.3 Purge unit The purge unit, driven by the paper feed motor, is comprised of the wiper, pump, cap, and carriage lock unit. The wiper unit keeps the BJ cartridge head face in good condition to ensure high quality printing while the suction function ensures that the ink in the nozzle can be easily discharged. When not in use, the unit protects the BJ cartridge with its cap and secures the carriage by locking it in place. 3.1.4 Paper feed unit The mechanical portion of the paper feed unit is comprised of the pick-up unit, paper feed unit, and paper ejection unit. Pick-up unit Paper is supplied either from the auto-sheet feeder in auto paper feed mode, or from the manual feed slot in manual paper feed mode. The auto-sheet feeder, driven by the paper feed motor, can be loaded with various sizes of paper up to legal size and automatically supplies paper (picks up and delivers the paper to the paper feed unit). Paper feed unit The paper feed unit, driven by the paper feed motor, turns the feed roller to horizontally move the paper beneath the BJ cartridge print head while keeping the paper level on the platen without cockling. To manually feed paper through this printer, use the RESUME button, as there is no paper feed knob. Paper ejection unit The printed paper is ejected by the eject rollers into the paper eject tray. 4-18