Craftsman 18178 Operation Manual - Page 5

Contact Trip Pad Storage

|

View all Craftsman 18178 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 5 highlights

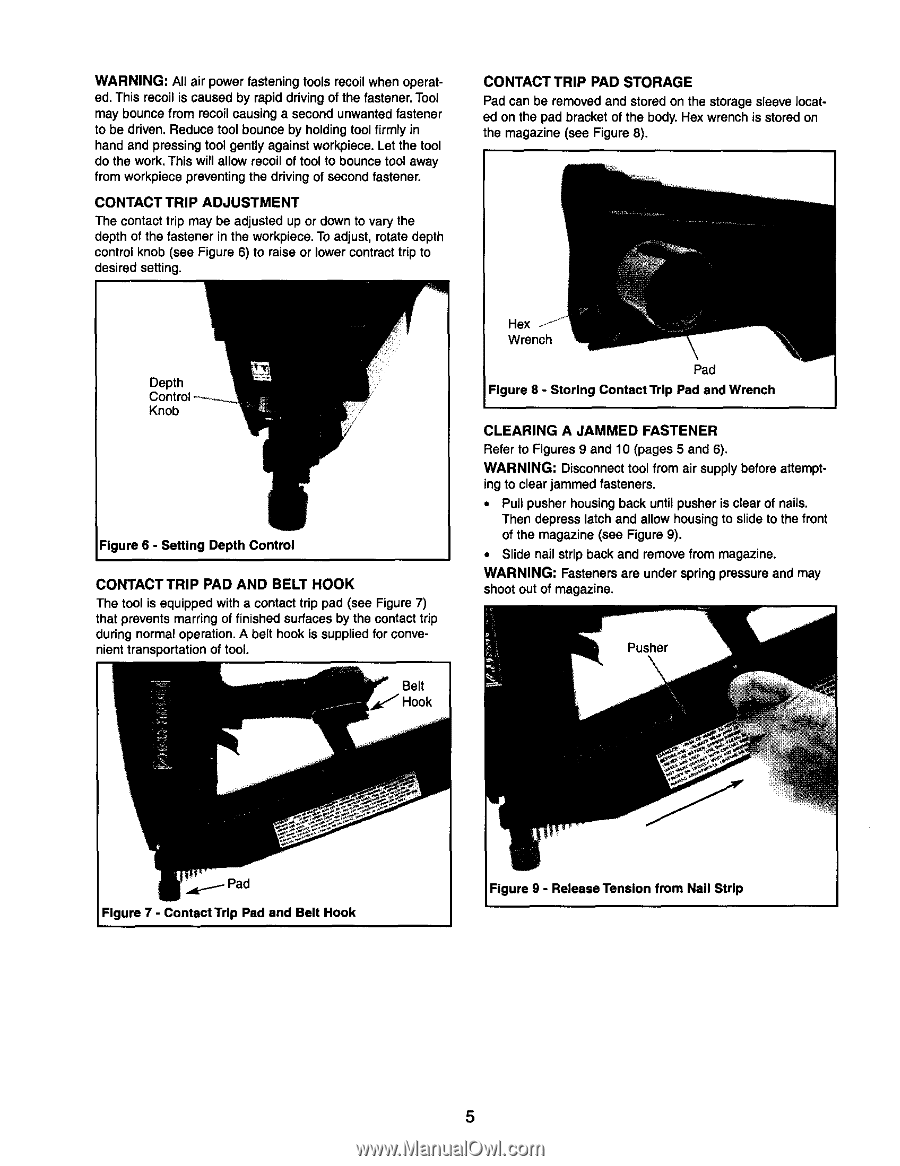

WARNING: All air power fastening tools recoil when operated. This recoil is caused by rapid driving of the fastener. Tool may bounce from recoil causing a second unwanted fastener to be driven. Reduce tool bounce by holding tool firmly in hand and pressing tool gently against workpiece. Let the tool do the work, This will allow recoil of tool to bounce tool away from workpiece preventing the driving of second fastener. CONTACT TRIP ADJUSTMENT The contact trip may be adjusted up or down to vary the depth of the fastener in the workpiece. To adjust, rotate depth control knob (see Figure 6) to raise or lower contract trip to desired setting. CONTACT TRIP PAD STORAGE Pad can be removed and stored on the storage sleeve located on the pad bracket of the body. Hex wrench is stored on the magazine (see Figure 8). Depth Knob Figure 6 - Setting Depth Control CONTACT TRIP PAD AND BELT HOOK The tool is equipped with a contact trip pad (see Figure 7) that prevents marring of finished surfaces by the contact trip during normal operation. A belt hook is supplied for convenient transportation of tool. Belt Hex _,/" Wrench Pad Figure 8 - Storing Contact Trip Pad and Wrench CLEARING A JAMMED FASTENER Refer to Figures 9 and 10 (pages 5 and 6). WARNING: Disconnect tool from air supply before attempt. ing to clear jammed fasteners. • Pull pusher housing back until pusher is clear of nails. Then depress latch and allow housing to slide to the front of the magazine (see Figure 9). • Slide nail strip back and remove from magazine. WARNING: Fasteners are under spring pressure and may shoot out of magazine. Figure 7 - Contact Trip Pad end Belt Hook Figure 9 - Release Tension from Nail Strip 5