Cub Cadet ZT1 42 Operation Manual - Page 16

Service And Maintenance - oil filter

|

View all Cub Cadet ZT1 42 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 16 highlights

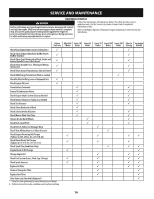

SERVICE AND MAINTENANCE MAINTENANCE SCHEDULE WARNING Before performing any type of maintenance/service, disengage all controls and stop the engine. Wait until all moving parts have come to a complete stop. Disconnect spark plug wire and ground it against the engine to prevent unintended starting. Always wear safety glasses during operation or while performing any adjustments or repairs. Follow the maintenance schedule given below. This chart describes service guidelines only. Use the Service Log column to keep track of completed maintenance tasks. Refer to the Engine Operator's Manual for engine maintenance items listed in the table below. Before Each use Check/Clean Engine Intake Screens & Cooling Fans # Check/Clean Exhaust Manifold, Muffler Pipe & Muffler Shields # Check/Clean Top & Underside of Deck, Under and Around Spindle Covers & Belt Area # Check/Clean Around Fuses, Wiring and Wiring Harnesses # Check/Clean Around Transmission, Axle and Fans # Check/Add/Change Transmission Fluid as needed Check Air Filter for Dirty, Loose or Damaged Parts Check Engine Oil Level Clean Battery Terminals Grease All Lubrication Points Check Engine Intake Screen/Clean as Needed Check Blades/Sharpen or Replace as Needed Check Tire Pressure Check/Clean Underside of Deck Check Safety Interlock System Check Mower Blade Stop Time Inspect & Lube Deck Wheels Check Deck Level/Pitch Check Belts & Pulleys for Damage/Wear Check That All Hardware is in Place & Secure Check Engine Mounting Bolt Torque (Tighten to 325-450 in.-lbs. (37-50 N-m)) Check Blade Mount Nut Torque (Tighten to 70-90 ft. lbs. (95-122 N-m)) Check Spark Plug Condition & Gap Engine Break-In Oil Change Change Engine Oil Check Fuel System (Lines, Tank, Cap, Fittings) Check Spark Arrestor Replace Oil Filter Clean or Change Air Filter Replace Fuel Filter Have Valve Lash Checked & Adjusted * * -- Have this item performed by an authorized service dealer #-- Perform more often in dry conditions and/or when mulching AfterFirst Every 10 5Hours Hours Every 25 Hours Every 50 Every 100 Every 200 Hours Hours Hours Prior to See Engine Storing Manual 16