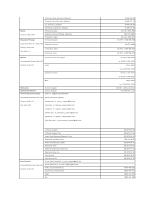

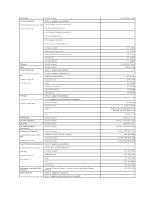

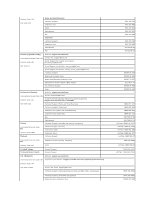

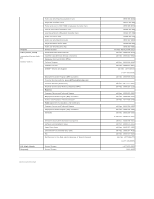

Dell PowerVault 122T LTO Dell PowerVault 122T DLT VS80 Autoloader User's Guide - Page 16

Media, SCSI ID, Autoloader Performance, Cleaning, Media Compatibility, Media Attention LED Issues - 2 autoloader tape drive

|

View all Dell PowerVault 122T LTO manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 16 highlights

autoloader Operator Panel controls. l Allow the tape drive to complete all operations, and then try unloading the tape using the autoloader Operator's Panel controls. l Make sure that the backup software is not reserving the slot or preventing the tape drive from ejecting the cartridge. The backup software needs to cancel the reservation and any hold it has on the tape drive. Temporarily disconnecting the autoloader from the host server eliminates the host and its software as a problem source. l Contact your service representative. Tape lodged in storage slot. l See "Removing Lodged Cartridges". Media Cleaning or data cartridge incompatible with drive. l Make sure you are using cleaning and data cartridges that are compatible with the drive. The autoloader automatically unloads incompatible cartridges to their original slots. Cannot write to or read from a tape. l Make sure that the cartridge is write enabled (see "Write-protecting Cartridges"). l Make sure that the cartridge is a DLTtapeIV that has not been written using an incompatible format. The drive can read, but not write, a DLT4000 formatted tape. l Make sure that the cartridge has not been exposed to harsh environmental or electrical conditions and is not physically damaged in any way. l Many backup applications do not read or write to cartridges that were created using a different backup application. In this case, you may have to perform an erase, format, or label operation on the cartridge. l Make sure you understand any data protection or overwrite protection schemes that your backup application may be using, which could prevent you from writing to a given cartridge. l Retry the operation with a different, known good tape. l Clean the tape drive (see "Cleaning the Tape Drive"). SCSI ID Changed drive SCSI ID, but the host server does not recognize the new ID. l Make sure that all SCSI devices on the same bus have unique ID numbers. l If the SCSI bus is narrow (50-pin), only SCSI IDs 0 through 7 are available. l Make sure that you cycle power on the autoloader after changing the SCSI ID. l Reboot the host server. Autoloader Performance The autoloader is not efficiently backing up data. l Check the network bandwidth from the host computer. If you are backing up data over a network, consider comparing to a local-only backup. l Make sure that the autoloader is on its own SCSI bus and not daisy-chained to another tape drive or to the hard drive being backed up. l Clean the tape drive (see "Cleaning the Tape Drive"). l Try a new cartridge. A marginal cartridge can cause performance problems due to bad spots on the tape requiring retries. l Make sure that the data is being compressed. l Check the size of the files. Small file size can impact performance. l Confirm that the backup application is utilizing block sizes of at least 32 KB, preferably 64 KB. Refer to your application's documentation for details. Cleaning Recurring cleaning message. l Make sure you are using a DLT1 compatible cleaning cartridge. l Replace the existing cleaning cartridge with a new one. l If the Media Attention LED is cleared using a cleaning cartridge and then immediately reappears after a particular data cartridge is reloaded, that data cartridge might be contaminated. If this occurs, check that the data cartridge can be read, back up data from the suspect cartridge to another cartridge, and then discard the suspect cartridge. The Clean Drive LED is illuminated. l Indicates that 250 tape motion hours have passed since you last cleaned the tape drive. l Clean the tape drive (see "Cleaning the Tape Drive"). Cannot load the cleaning cartridge. l Make sure you are using a DLT1 compatible cleaning cartridge (see "Cleaning the Tape Drive"). l Contact your service representative. Media Compatibility Media format invalid for drive type. l You attempted to load incompatible media into the tape drive. Ensure your media and format is compatible with a DLT VS80 tape drive (see "Using Cartridges"). Media is labeled as write protected by the host server, but restore from tape successful. Media is rejected by the tape drive. Restore from tape NOT successful. l Media with the DLT4000 format was loaded into the tape drive. The data is readable, but the media must be bulk-erased before the tape drive can write to this cartridge. l You attempted to load damaged or incompatible media or the tape drives' read/write head is dirty. Try replacing the cartridge or cleaning the drive. Media Attention LED Issues Contamination by loose debris. l Avoid contamination by ensuring that the autoloader is installed in a clean, contamination-free environment. Cartridges should be stored vertically in their plastic cases. Continue cleaning the tape drive as requested. Contamination by head staining. (caused by adhesion of chemicals that are present in the tape media to the head surface) Non-acclimated media l One or two passes with a cleaning cartridge should resolve the Media Attention LED caused by normal head staining. If a cleaning cartridge is unsuccessful in resolving a cleaning light after three or more attempts, contact your service representative. l A cartridge should be acclimated for a minimum of 24 hours before being used, particularly if it has been stored at a substantially different temperature or level of humidity than the tape library. Wrong cleaning cartridge l Make sure you are using a DLT1 compatible cleaning cartridge. Bad/defective/contaminated media l If the Media Attention LED is cleared using a cleaning cartridge and then immediately reappears each time a particular cartridge is reloaded, and you have confirmed that the suspect cartridge in not invalid, that cartridge should be suspected as being contaminated. If this occurs, export the cartridge, clean the tape drive again, and then load a known good cartridge. In some cases, a cartridge can be worn out, have bad calibration tracks, have been improperly degaussed, or have a bad tape directory recorded by another drive type such as DLT7000 or DLT8000.