E-Z-GO Shuttle 22 TXT - Electric Owner Manual - Page 58

TROUBLESHOOTING, Hydrometer

|

View all E-Z-GO Shuttle 22 TXT - Electric manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 58 highlights

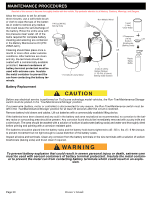

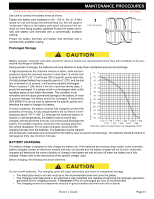

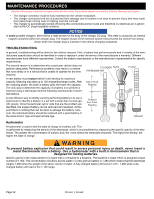

MAINTENANCE PROCEDURES Read all of this manual to become thoroughly familiar with this vehicle. Pay particular attention to all Notices, Cautions, Warnings, and Dangers. • The charger connector must be fully inserted into the vehicle receptacle. • The charger connector/cord set is protected from damage and is located in an area to prevent injury that may result from personnel running over or tripping over the cord set. • The charger is automatically turned off during the connect/disconnect cycle and therefore no electrical arc is gener- ated at the DC plug/receptacle contacts. NOTICE In some portable chargers, there will be a rattle present in the body of the charger DC plug. This rattle is caused by an internal magnet contained within the charger plug. The magnet is part of the interlock system that prevents the vehicle from being driven when the charger plug is inserted in the vehicle charging receptacle. TROUBLESHOOTING In general, troubleshooting will be done for two distinct reasons. First, a battery that performs poorly and is outside of the manufacturers specification should be identified in order to replace it under the terms of the manufacturer's warranty. Different manufacturers have different requirements. Consult the battery manufacturer or the manufacturer's representative for specific requirements. The second reason is to determine why a particular vehicle does not perform adequately. Performance problems may result in a vehicle that runs slowly or in a vehicle that is unable to operate for the time required. CYLINDER BULB THERMOMETER FLOAT A new battery must mature before it will develop its maximum capacity. Maturing may take up to 100 charge/discharge cycles. After the maturing phase, the older a battery gets, the lower the capacity. The only way to determine the capacity of a battery is to perform a load test using a discharge machine following manufacturer's recommendations. Add to Float Reading A cost effective way to identify a poorly performing battery is to use a hydrometer to identify a battery in a set with a lower than normal specific gravity. Once the particular cell or cells that are the problem are identified, the suspect battery can be removed and replaced. At this point there is nothing that can be done to salvage the battery; however, the individual battery should be replaced with a good battery of the same brand, type and approximate age. Subtract from Float Reading WEIGHT Hydrometer A hydrometer is used to test the state of charge of a battery cell. This is performed by measuring the density of the electrolyte, which is accomplished by measuring the specific gravity of the electrolyte. The greater the concentration of sulfuric acid, the more dense the electrolyte becomes. The higher the density, the higher the state of charge. To prevent battery explosion that could result in severe personal injury or death, never insert a metal thermometer into a battery. Use a hydrometer with a built in thermometer that is designed for testing batteries. Specific gravity is the measurement of a liquid that is compared to a baseline. The baseline is water which is assigned a base number of 1.000. The concentration of sulfuric acid to water in a new golf car battery is 1.280 which means that the electrolyte weighs 1.280 times the weight of the same volume of water. A fully charged battery will test at 1.275 - 1.280 while a discharged battery will read in the 1.140 range. Page 52 Owner's Guide