Hayward TriStar VS TriStar VS Manual - Page 27

Shaft Seal Change Instructions

|

View all Hayward TriStar VS manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 27 highlights

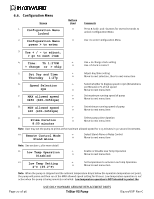

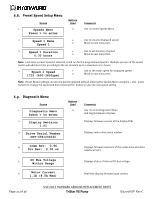

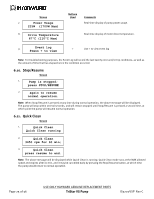

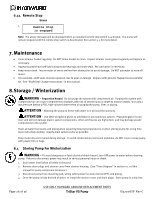

9. Shaft Seal Change Instructions IMPORTANT SAFETY INSTRUCTIONS PLEASE READ AND FOLLOW ALL INSTRUCTIONS When servicing electrical equipment, basic safety precautions should always be observed including the following. Failure to follow instructions may result in injury. WARNING - To reduce risk of injury, do not permit children to use this product. Disconnect all electrical power service to pump before beginning shaft seal replacement. Only qualified personnel should attempt rotary seal replacement. Contact your local authorized Hayward Dealer or service center if you have any questions. Refer to Figure 10.1-1 for pump component locations. Exercise extreme care in handling both the rotating and the stationary sections of the two-part replacement seal. Foreign matter or improper handling will easily scratch the graphite and ceramic sealing surfaces. 9.1. Removing the Motor Assembly 1. Remove the six (6) 5/16" x 2" hex head bolts (item #17), which hold the motor assembly to the pump/strainer housing (item #3), using a 1/2" wrench or socket. 2. Slide the motor assembly out of the pump/strainer housing (item #3), exposing the diffuser (item #9). Remove the two diffuser screws (item #7), and pull the diffuser (item #9) off of the seal plate (item #15) to expose the impeller (item #12). 9.2. Removing the Impeller 3. Remove the motor fan shroud by removing the four (4) screws and pulling the shroud away from the motor. 4. To prevent the motor shaft from turning, secure using a 5/16" hex wrench in the socket on the motor shaft. 5. Rotate the impeller screw (item #10) clockwise (note that screw has left-hand thread) and remove. Remove the impeller (item #12) by rotating counterclockwise. 9.3. Removing the Ceramic Seat 6. Remove the spring seal assembly (item #13) and seal plate (item #15) from the motor by removing the four (4) 3/8" x 1" bolts (item #18) that secure it to the motor, using a 9/16" wrench or socket. Remove the motor support bracket (item #20) from the seal plate (item #15). 7. Press the ceramic seat with rubber cup out of the seal plate (item #15). If tight, use a small screwdriver to tap seal out. STOP - Clean all recesses & parts to be reassembled. Inspect gaskets & replace if necessary. 9.4. Seal Installation 8. Clean and lightly lubricate the motor shaft and seal recesses in the seal plate (item #15) with a dilute solution of non-granulated liquid-type soap. Gently wipe the polished face of the ceramic seal with a soft cotton cloth. Lubricate the rubber cup on the ceramic seat and press it firmly into the recess of the seal plate (item #15), with the polished ceramic surface facing out. 9. Reassemble the motor to the seal plate (item #15) using the four (4) 3/8" x 1" bolts (item #18), and re-attach the motor support (item #20) to the seal plate (item #15). 10. Gently wipe the black, polished surface of the spring seal assembly (item #13) with a soft cotton cloth. 11. Press the spring seal assembly (item #13) onto the motor shaft, with the black polished surface facing the ceramic seat. Page 27 of 36 USE ONLY HAYWARD GENUINE REPLACEMENT PARTS TriStar VS Pump IS3200VSP Rev-C