Hitachi NT65MA2 Instruction Manual - Page 11

Air Supply - compressor

|

UPC - 717709007727

View all Hitachi NT65MA2 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 11 highlights

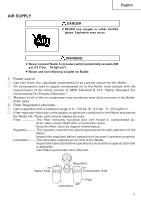

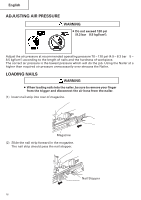

AIR SUPPLY English DANGER ● NEVER use oxygen or other bottled gases. Explosion may occur. WARNING ● Never connect Nailer to pressure which potentially exceeds 200 psi (13.7 bar 14 kgf/cm2). ● Never use non relieving coupler on Nailer. 1. Power source ⅜ Use only clean, dry, regulated compressed air as a power source for this Nailer. ⅜ Air compressors used to supply compressed air to this Nailer must comply with the requirements of the latest version of ANSI Standard B 19.3 "Safety Standard For Compressors For Process Industries." ⅜ Moisture or oil in the air compressor may accelerate wear and corrosion in the Nailer. Drain daily. 2. Filter-Regulator-Lubricator ⅜ Use a regulator with a pressure range of 0 - 120 psi (0 - 8.3 bar 0 - 8.5 kgf/cm2). ⅜ Filter-regulator-lubricator units supply an optimum condition for the Nailer and extend the Nailer life. These units should always be used. Filter The filter removes moisture and dirt mixed in compressed air. Drain daily unless fitted with an automatic drain. Keep the filter clean by regular maintenance. Regulator ......... The regulator controls the operating pressure for safe operation of the Nailer. Inspect the regulator before operation to be sure it operates properly. Lubricator ........ The lubricator supplies an oil mist to the Nailer. Inspect the lubricator before operation to be sure the supply of lubricant is adequate. Use Hitachi pneumatic tool lubricant. Nailer Side Regulator Compressor Side Lubricator Filter 11