Hitachi NV65AH Instruction Manual - Page 13

Methods Of Operation, Warning - jamming

|

UPC - 717709004689

View all Hitachi NV65AH manuals

Add to My Manuals

Save this manual to your list of manuals |

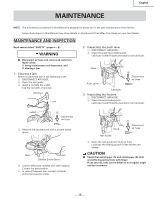

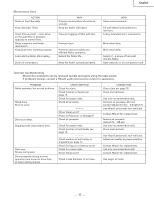

Page 13 highlights

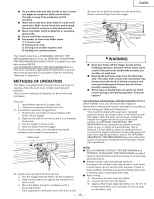

English ⅷ Do not drive nails into thin boards or near corners and edges of workpiece. Nails can be driven through or away from workpiece and hit someone. ⅷ Never drive nails from both sides of a wall at the same time. Nails can be driven into and through the wall and hit a person on the opposite side. ⅷ Never use Nailer which is defective or operating abnormally. ⅷ Do not use Nailer as hammer. ⅷ Disconnect air hose from Nailer when: 1) it is not in use; 2) leaving work area; 3) moving it to another location; and 4) handing it to another person. As soon as the desired number of nails have been driven, remove finger from the trigger. 3 1 Previously pull the trigger This Hitachi nailer has a STANDARD CONTACT TRIP MECHANISM (Bounce Fire). An OPTIONAL SEQUENTIAL TRIP MECHANISM kit (SINGLE SHOT) is available as order part number 881973. THE STANDARD CONTACT TRIP MECHANISM (Bounce Fire) is for use where rapid fastener placement is desired and must be operated in accordance with the following "Methods of Operation". METHODS OF OPERATION This Nailer is equipped with the push lever and does not operate unless the push lever is depressed (upward position). There are two methods of operation to drive nails with this Nailer. WARNING ⅷ Keep your finger off the trigger except during fastening operation, because serious injury could result if the push lever accidentally contacts you or others in work area. ⅷ Keep hands and body away from the discharge area. The nailer with contact trip mechanism may bounce from the recoil of driving a fastener and unwanted subsequent fastener may be driven, possibly causing injury. ⅷ Some types of loaded nails can spark out of the muzzle during a nail driving operation. Exericise caution! They are: 1. Intermittent operation (Trigger fire): 2. Continuous operation (Push lever fire): (1) Intermittent operation (Trigger fire) 1 Position the nail outlet on the workpiece with finger off the trigger. 2 Depress the push lever firmly until it is completely depressed. 3 Pull the trigger to drive a nail. 4 Remove finger from the trigger. To drive another nail, move the Nailer along the workpiece and repeat this procedure. Push Lever 2 THE OPTIONAL SEQUENTIAL TRIP MECHANISM (SINGLE SHOT PARTS) is for use where precision fastener placement is desired and must be operated in accordance with the following "Method of Operation". You must first depress the push lever (upward position) where you wnat to drive a nail and then pull the trigger. After the each nail is driven, completely release the trigger and lift the tool off the work surface. An OPTIONAL SEQUENTIAL TRIP MECHANISM may reduce the possibility of bodily injury to you or others in the work area. This is because it is less likely to drive an unwanted nail if you keep the trigger pulled and accidentally bump the push lever against yourself or others. An OPTIONAL SEQUENTIAL TRIP MECHANISM may also reduce the speed of operation compared to the standard contact trip mechanism. 3 Trigger (2) Continuous operation (Push lever fire) 1 Pull the trigger with the Nailer off the workpiece. 2 Depress the push lever against the workpiece to drive a nail. 3 Move the Nailer along the workpiece with a bouncing motion. Each depression of the push lever will drive a nail. NOTE: ⅷ Both STANDARD CONTACT TRIP MECHANISM and OPTIONAL SEQUENTIAL TRIP MECHANISM are safe if used as described above and accroding to all warnings and instructions. ⅷ Always handle nails and package carefully. If dropped, the collated nails may break or come loose. In such cases, do not use the nails because, if used in that condition, nail feed may become faulty and result in missed nails or jamming of the nails. ⅷ After nailing: 1) disconnect air hose from the Nailer; 2) remove all nails from the Nailer; 3) supply a few drops (approximately 2 cc (.12 in3)) of Hitachi pneumatic tool lubricant into the air plug on the Nailer; and - 13 -