Hitachi VB16Y Instruction Manual - Page 19

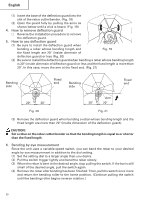

How to install deflection guard - rebar bender

|

UPC - 717709006256

View all Hitachi VB16Y manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 19 highlights

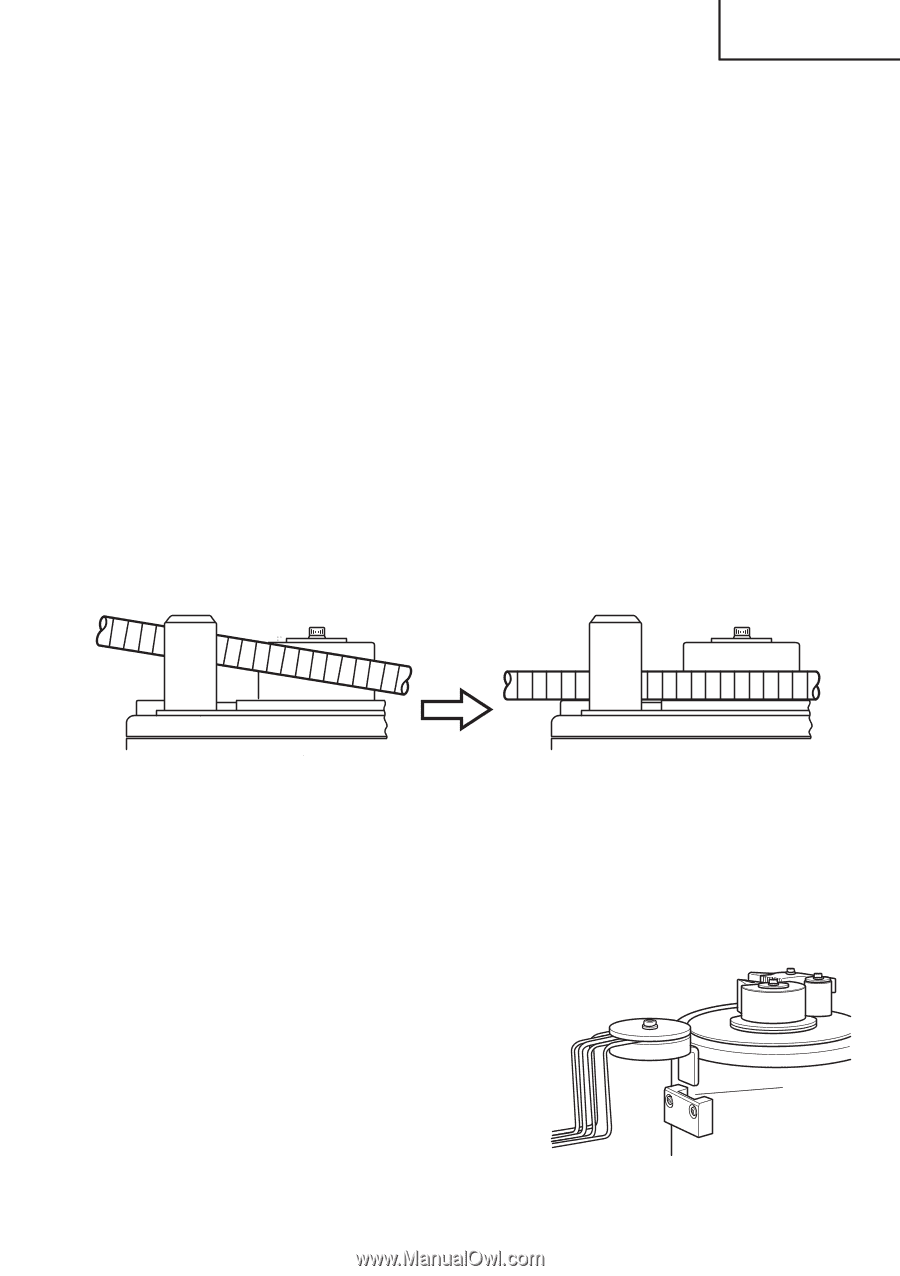

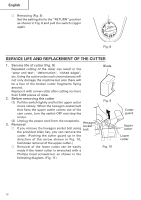

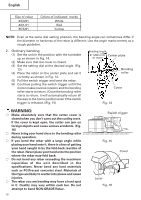

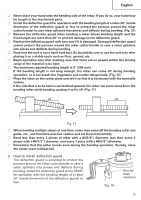

English ⅜ Never place your hand onto the bending side of the rebar. If you do so, your hand may be caught in the mechanical parts. ⅜ Install the deflection guard for operation with the bending length of a rebar 20" (inside dimension of the deflection guard) or less to protect the persons around the rebar cutter/bender in case rebar splinters into pieces and deflects during bending. (Fig. 21) ⅜ Remove the deflection guard when bending a rebar whose bending length and the fixed length are more than 20" to prevent damage to the deflection guard. ⅜ Replace the deflection guard with new one if it is damaged. Damaged deflection guard cannot protect the persons around the rebar cutter/bender in case a rebar splinters into pieces and deflects during bending. ⅜ Note that the unit is not a hand-held tool. Be absolutely sure to use the unit only after placing it on a stable spots such as floor, ground, etc. ⅜ Begin operation only after marking sure that there are no people within the turning range of the material to be bent. ⅜ The minimum required bending length is 8" (200 mm). If the bending length is not long enough, the rebar can come off during bending operation, or it can break into fragments and scatter dangerously. (Fig. 14) ⅜ Place the rebar on the center plate and set it so that it is horizontal with the turntable surface. If the side that is to be bent is set inclined upward, the rebar can come loose from the bending roller while bending causing it to fly off. (Fig. 17) Fig. 17 ⅜ When bending multiple rebars at one time, some may come off the bending roller and guide, etc., and therefore exercise caution and set them horizontally. ⅜ Bend less than every 3 pieces of rebar with a #3(3/8") diameter, less than every 2 pieces with a #4(1/2") diameter, and every 1 piece with a #5(5/8") diameter. ⅜ Remember that the cutter moves even during the bending operation, thereby, close the cutter cover without fail. 3. How to install deflection guard The deflection guard is provided to protect the persons around the rebar cutter/bender in case a rebar splinters into pieces and deflects during bending. Install the deflection guard to the VB16Y for operation with the bending length of a rebar 20" (inside dimension of the deflection guard) or less. Fig. 18 Slot for base insertion 19