Kenmore 9791 Installation Instructions - Page 5

Thelaundrycentermaybeexhausted, four4wayswithrear, flushinstallation

|

View all Kenmore 9791 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 5 highlights

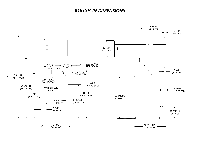

...... Thelaundrycentermaybeexhaustefdour(4)wayswithrear flushinstallation: 1.Straight back 2. Down (8 inch [20.32 cm] length of 4 inch [10.16 cm] rigid duct and 1 elbow down) 3. Left (8 inch [20.32 cm] length of 4 inch [10.16 cm] rigid duct, 1 elbow down and 1 elbow left) 1.Installation MUST conform with local codes, or in the absence of local codes, with the National Fuel Gas Code, ANSI Z223.1 (latest edition) or in Canada, the current AN/CGA B149. 4. Right (8 inch [20.32 cm] length of 4 inch [10.16 cm] rigid duct, 1 elbow down and 1 elbow right) To exhaust up, add an 11 inch (27.94 cm) length of standard 4 inch (10.16 cm) diameter duct and a 90 ° elbow. The unit will be positioned about 41/2inches (11.43 cm) away from the wall 2.The gas supply line should be of 1/2 inch (1.27 cm) pipe. 3.If codes allow, flexible metal tubing may be used to connect your dryer to the gas supply line. The tubing MUST be constructed of stainless steel or plastic-coated brass. (flush to wall exhausting may be done by going below the dryer then sideways). An exhaust hood positioned to line up with the dryer exhaust can be installed 4.The gas supply line MUSThave an individual shutoff valve. 5.A 1/8 inch (0.32 cm) N. F T. plugged tapping, accessible for test gage connection, MUST be installed immediately upstream of the gas supply connection to the dryer. directly through the outside wall. To exhaust to the side or down, add an 8 inch (20.32 cm) length of standard 4 inch (10.16 cm) diameter duct and a 90 ° elbow. 6.The dryer and its individual shutoff valve MUST be disconnected from the gas supply piping system during any pressure testing of the gas supply piping system at test pressures equal to or less than 1/2 psig (3.45 kPa). 7.The dryer MUSTbe isolated from the gas supply piping system by closing its individual manual shutoff valve during any pressuretesting of the gas supply piping system at test pressures equal to or less than 1/2 psig (3.45 kPa). DO NOT INSTALL YOUR LAUNDRY CENTER: 1.In an area exposed to dripping water or outside weather conditions. 2.In an area where it will come in contact with curtains or drapes. 3.On carpet. Floor MUSTbe solid with a maximum slope of 1 inch (2.54 cm). INSTALLATION IN RECESSOR CLOSET 1.A laundry center installed in a bedroom, bathroom, recess or closet, MUSTbe exhausted outdoors. 2.No other fuel burning appliance shall be installed in the same closet as the Gas laundry center. 3.Your laundry center needs the spacearound it for proper ventilation. DO NOT INSTALL YOUR LAUNDRY CENTER IN A CLOSET WITH A SOLID DOOR. 4.A minimum of 120 square inches (774.2 square cm) of opening, equally divided at the top and bottom of the door, is required. Air openings are required to be unobstructed when a door is installed. A Iouvered door with equivalent air openings for the full length of the door is acceptable. 5.The following illustrations show minimum clearance dimensions and air openings for proper operation in a recess or closet installation. 0 IN. 0 IN. 1 IN. ; ; ',', 0 IN. (0 _(0 c M) (2.54CM)'I,_ _(0 CM) 60 SQ.iN. (387.1 SQ. CM) 60SQ._N. (387.1 SQ. CM) I_ II III (387.1 SQ. CM) Closet Door 5 60 SQ. IN. _ I