Konica Minolta magicolor 1690MF Service Manual - Page 94

Control termination timing - i c low

|

View all Konica Minolta magicolor 1690MF manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 94 highlights

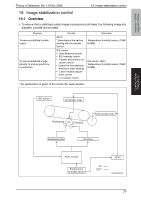

magicolor 1680MF magicolor 1690MF COMPOSITION/ OPERATION Theory of Operation Ver. 1.0 Nov. 2008 17. Fusing section D. Control start decision • Either of the following two control start decisions is made according to the temperature detected by the temperature/humidity sensor. The fusing temperature during the print cycle varies depending on the type of the start control carried out, either low temperature start control or ordinary start control. Control start decision Low temperature start control Ordinary start control Environment upon start The temperature/humidity sensor detects a temperature lower than the predetermined value. The temperature/humidity sensor detects a temperature equivalent to, or higher than, the predetermined value. 17.3.2 Wait control • Control is provided to ensure that the temperatures at different parts of the fusing unit reach a constant level during the wait state. A. Control start timing • At the end of the warm-up control • At the end of the post-print cycle control (print start control) B. Control termination timing • The front cover is opened and closed. • A malfunction or media misfeed occurs. 17.3.3 Print control • To ensure a good fixing level and light transmission performance of the OHP transparencies, the fusing speed and fusing roller temperature are controlled. A. Control start timing • A print request is received. B. Control termination timing • A malfunction or media misfeed occurs. C. Print control temperatures • The fusing roller temperature is set according to the type of media, main body interior temperature (as measured by the temperature/humidity sensor), and warm-up start decision. • For types of media other than plain paper, the fusing speed is controlled at the 1/2 speed. D. Print control temperature adjustments • The temperature during print control is adjusted using the menu available from the control panel. The temperature can, however, be decreased only. • Adjustment steps are 0°C, -5°C, and -10°C. 67