LiftMaster JDC Installation Manual - English French Spanish - Page 53

from OPEN/CLOSE/STOP, 120V, 240V, or 480V

|

View all LiftMaster JDC manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 53 highlights

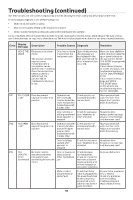

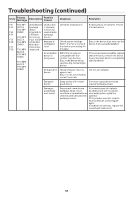

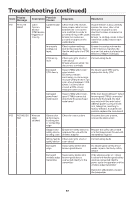

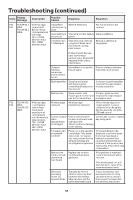

Troubleshooting (continued) Code Display Message Description Possible Causes Diagnosis Resolution F26 F26 OVER Motor drive AC input voltage Check whether the If 240V power is VOLT circuitry detected mis-selected transformer connector applied when 120V is an overvoltage (120V/240V is plugged in to the selected, damage to condition models only) connectors on the EMI filter other components of board marked '120V' or the operator electronics '240V.' may have occurred. Verify this matches the input Ensure voltage selection AC voltage supplied to the is corrected and verify operator. the operator functions. Door imbalance causes motor regeneration Inspect door for imbalance or broken springs repair or correct conditions resulting in excessive door imbalance AC power out of range Verify input AC voltage: Measure AC voltage between 'L1' and 'L2' terminals at EMI filter board input connector. Verify voltage is within specifications. If voltage is outside specifications, see resolution. Ensure the circuit supplying the operator is the correct voltage class for the operator (e.g. 120V, 240V, or 480V) If voltage is out of specification for the circuit, consult an electrician. F31 F31 OPEN Wall control Wall control Check that all buttons return Repair, clean, or replace F32 HELD buttons held/ buttons stuck to the normal state properly sticking buttons or F33 F32 CLOSE stuck for at least when released. controls as necessary. F34 HELD 1 minute. F33 STOP Open/Close/ Wiring short HELD Stop/SBC inputs circuit F34 SBC triggered for at Inspect wiring for open/ close/stop/SBC terminals for short circuits Correct any wiring faults found HELD least 1 minute. Faulty accessory Disconnect accessories If problem is resolved by connected to from the terminals. disconnection of other OPEN/CLOSE/ external accessories, STOP/SBC suspect a wiring issue, terminals faulty accessory, or incompatible accessory. Faulty LCD wall control Swap wall control with known-good unit If known-good wall control resolves the issue, fault is with previous wall control Faulty powerhead main board Remove all accessories from OPEN/CLOSE/STOP/ SBC terminals. Ensure wall control is replaced with a known-good unit for diagnosis. Try power cycling the operator and restoring factory defaults. If problems persist, replace powerhead main PCBA 53