LiftMaster JDC Installation Manual - English French Spanish - Page 59

powerhead main board near the, wires match the labeling on

|

View all LiftMaster JDC manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 59 highlights

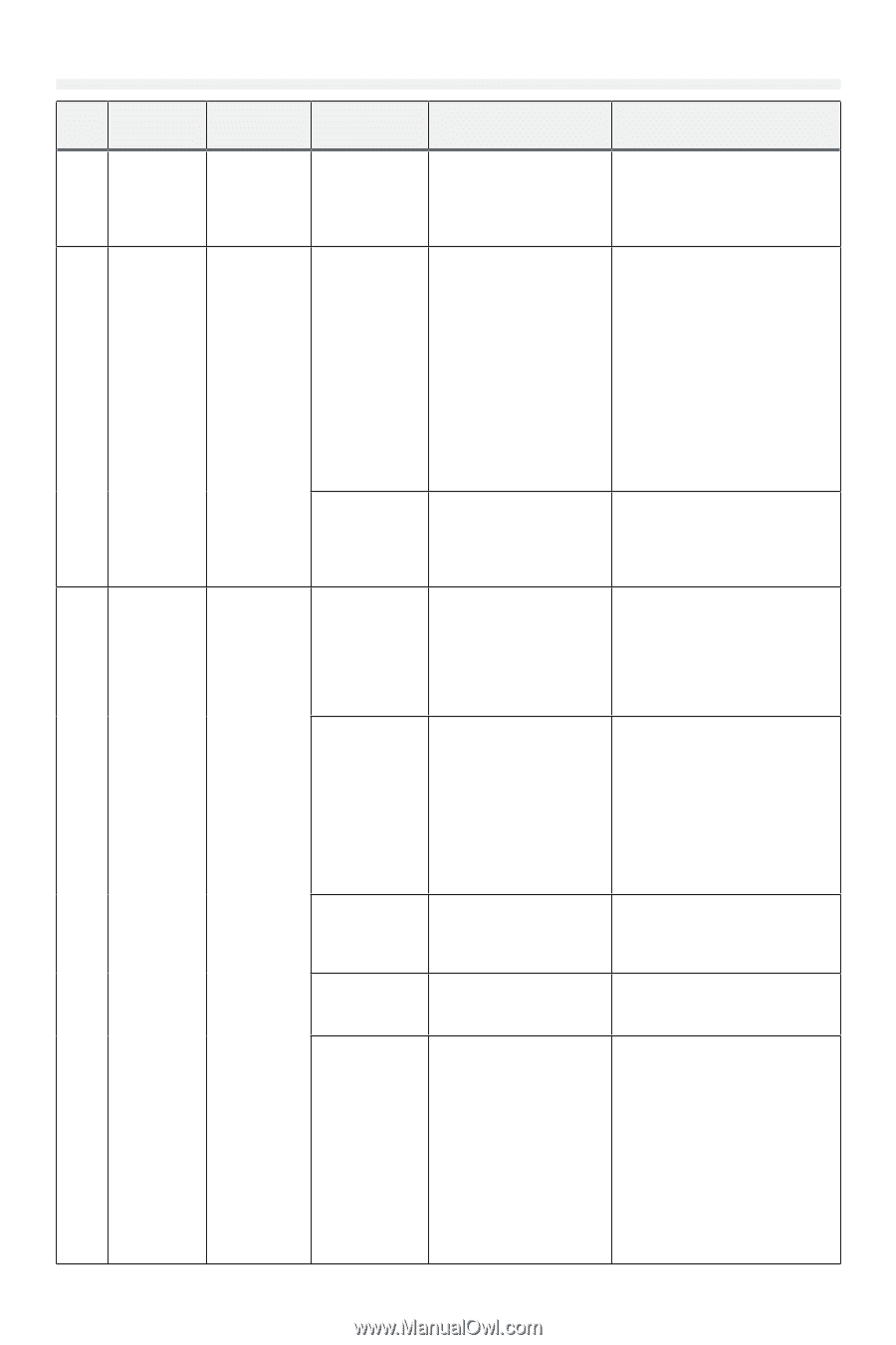

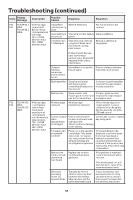

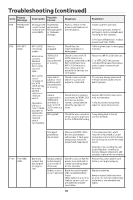

Troubleshooting (continued) Code Display Message F68 F68 WE CRITBATT F89 F89 WC DISC F91 F91 ENCODER Description Possible Causes Diagnosis Resolution Wireless edge The battery transmitter in the has low wireless edge battery transmitter is low Indicates wall Wall control is control is not intentionally detected disconnected Check battery condition in wireless edge transmitter Replace battery in wireless edge transmitter. See resolution Liftmaster strongly recommends using an LCD wall control with the operator. If the wall control is intentionally disconnected, this error can be cleared by placing a jumper wire between the WALL CTRL teminals on the powerhead main board. If the jumper is removed and a wall control reconnected, the system may require a power cycle to recognize the new wall control. Wall control is wired but off or not functional Check wall control for display backlight, text on the display, and function of open/close/stop buttons If LCD wall control isn't functioning properly, see diagnosis for fault 'LCD wall control is off or not functioning' The system has detected irregularities in the signals received from the encoder. Direction of rotation incorrect Watch operator output shaft when commanding operator to open. If output shaft rotates in the close direction, then rotation direction is incorrect. Ensure motor red and black wires match the labeling on the powerhead main board near the motor connector. Ensure reverse mount setting is set properly. System ID mismatch between powerhead main board and operator chassis can cause the encoder to not be recognized. Check that the system ID in the system information menu matches the model of the operator Main board system ID must match the operator. Replacement service kit main boards allow setting the system ID using the menu on the LCD wall control. Factory installed boards cannot have the System ID set manually. Door is drifting up or down due to imbalance when starting Check for excessive door imbalance Rebalance door Encoder wiring Inspect encoder cable Correct any issues found with fault for disconnection, bad encoder wiring connection, cut cable, etc. Encoder fault or encoder interface fault Go to limit learn process. Number displayed while in door limit learn mode is the encoder position. Jog door several inches in either direction and release button. Number displayed should change. Make sure to cancel changes or set limit again when finished. If encoder position does not change with door movement, ensure system ID in the system information menu matches the operator. If the system ID matches but the problem persists, the encoder, encoder wiring, and powerhead main board are suspect. Check all three for any visible damage. Replace or repair suspected faulty components. 59