LiftMaster SW420 SW420 S3 BOARD Manual - Page 27

Troubleshooting

|

View all LiftMaster SW420 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 27 highlights

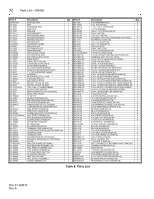

Troubleshooting 27 Troubleshooting When troubleshooting, one of the first things to do is try to isolate the problem area. The five (5) main areas to check out are: Power Accessories Operator's Primary Voltage Operator's Low Voltage Gear Reducer 1. Power Always use extreme caution! Some possible symptoms of power problems include: The obvious one is - the operator will not run. The operator runs slow. Circuit breakers or fuses keep tripping. Motor overload keeps tripping. Operator starts but then stops. 1A. Using a V.O.M. take a voltage reading at the control transformer's primary terminals. You should get a reading as follows: Nominal Volt. 120v. 230v. Min. 108 207 Max. 132 253 Table 7 If you get a reading that does not fall into the minimum/maximum area, then check out your main power supply. Also, make sure that the operator was ordered with the proper voltage and phase. Another item to check is the wire run from the power supply to the operator. Double check the gauge of the wire versus the distance. 1B. If the voltage reading is O.K. from 1A, then take the same voltage reading with the operator running. If voltage drops below the minimum with this reading, then there could be an excessive current draw somewhere. 1C. In some cases, power drops can occur at only specific times during the day or night. This can be caused by increased power demands in a general area at a specific time. Doc 01-G0610 Rev A