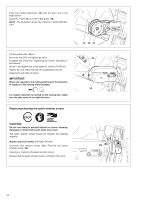

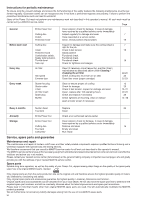

Makita EK7301 Owners Manual - Page 29

Special Accessories - parts list

|

View all Makita EK7301 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 29 highlights

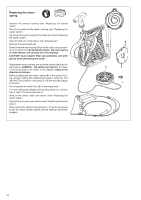

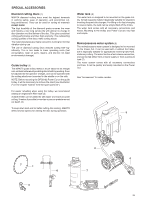

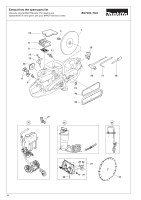

SPECIAL ACCESSORIES Diamond cutting discs (1) MAKITA diamond cutting discs meet the highest demands in working safety, ease of operation, and economical cutting performance. They can be used for cutting all materials except metal. The high durability of the diamond grains ensures low wear and thereby a very long service life with almost no change in disc diameter over the lifetime of the disc. This gives consistent cutting performance and thus high economy. The outstanding cutting qualities of the discs make cutting easier. The metal disc plates give highly concentric running for minimal vibration during use. The use of diamond cutting discs reduces cutting time significantly. This in turn leads to lower operating costs (fuel consumption, wear on parts, repairs, and last but not least environmental damage). Guide trolley (2) The MAKITA guide trolley makes it much easier to do straight cuts, while simultaneously enabling almost untiring working. It can be adjusted for the operator´s height, and can be operated with the cutting attachment mounted in the middle or on the side. NOTE: Before mounting the DPC8132 Power Cut on the guide trolley, it will be necessary to remove the stand (see illustration (*) in the chapter "Extract from the spare parts list"). For easier refuelling when using the trolley, we recommend adding an angled tank filler neck (3). A depth limiter can be added for still easier and more accurate cutting. It makes it possible to maintain a precise predetermined cut depth (4). To keep down dust and for better cutting‑disc cooling, MAKITA offers several options for wetting the disc during operation. Water tank (5) The water tank is designed to be mounted on the guide trolley. Its high capacity makes it especially suitable for situations involving frequent site changes. For filling or for fast changing to reserve tanks, the tank can be simply lifted off the trolley. The water tank comes with all necessary connections and hoses. Mounting to the trolley and Power Cut are very fast and simple. Mains/pressure water system (6) The mains/pressure water system is designed to be mounted on the Power Cut. It can be used with or without the trolley, but is especially suitable for applications involving hand‑held, stationary cutting. The water line has a fast‑release connection, and can be fed either from a mains supply or from a pressure tank (7). The water system comes with all necessary connections and lines. It can be quickly and easily mounted on the Power Cut. See "Accessories" for order number. 5 1 6 3 2 7 4 29