Singer 7258 Stylist Instruction Manual - Page 42

Straight Stitching

|

View all Singer 7258 Stylist manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 42 highlights

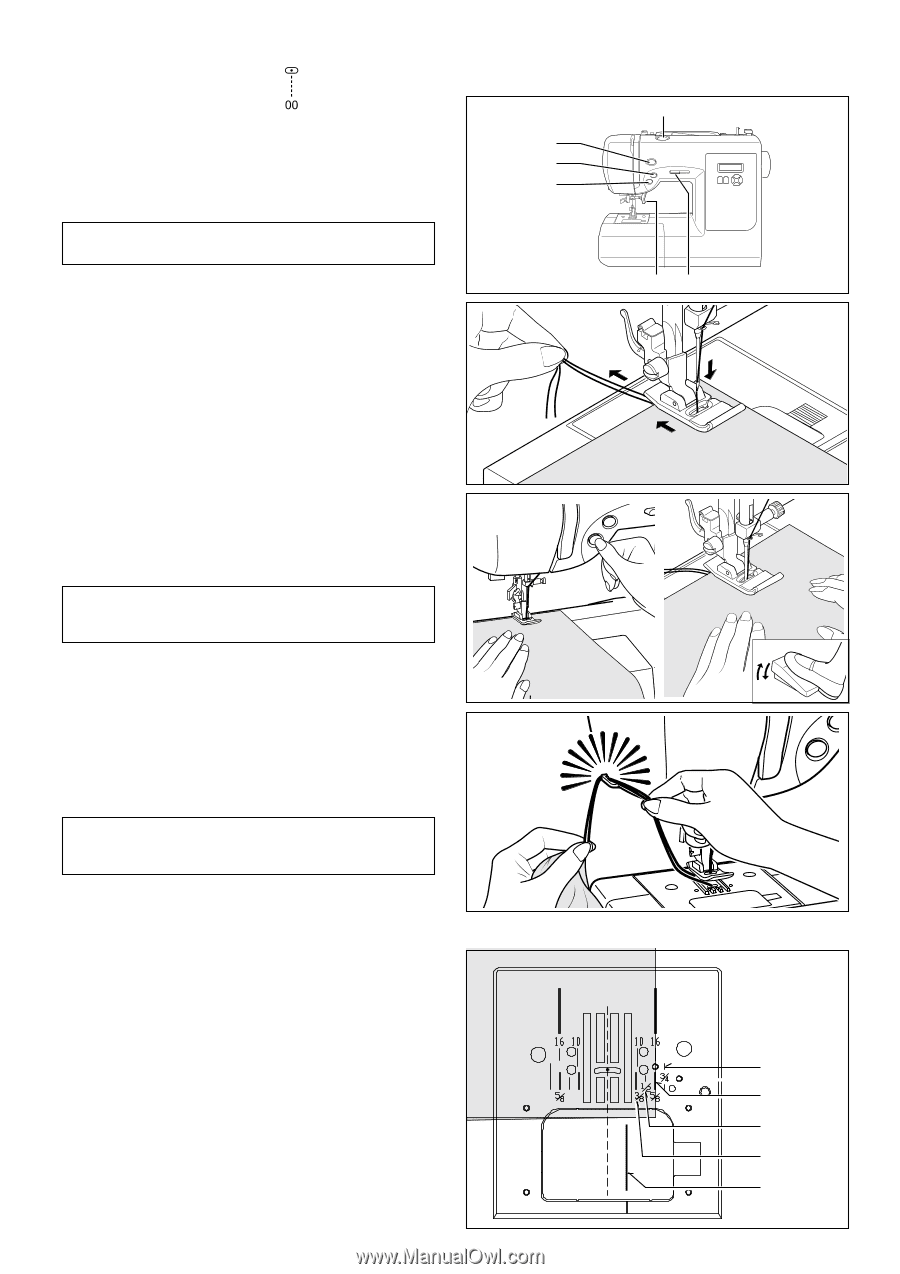

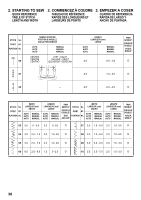

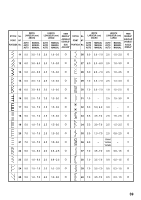

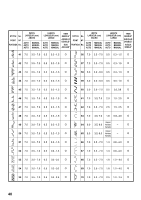

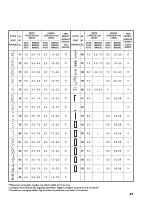

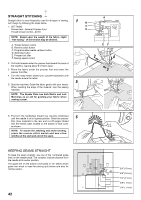

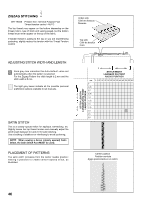

STRAIGHT STITCHING A Straight stitch is most frequently used for all types of sewing. Let's begin by following the steps below. 1 B 1. SETTINGS C Presser foot - General Purpose Foot D Thread tension control - AUTO NOTE: Based upon the weight of the fabric, slight "fine tuning" of the tension may be desired. A. Thread tension control B. Reverse stitch button C. Programmable needle up/down button D. Start/stop button E. Presser foot lifter F. Sewing speed control EF 2 4 2. Pull both threads under the presser foot toward the back of the machine, leaving about 6" (15cm) clear. 3. Place the fabric under the presser foot and lower the 3 presser foot lifter. 4. Turn the hand wheel toward you (counter-clockwise) until the needle enters the fabric. 5 5. Start the machine. Guide the fabric gently with your hands. When reaching the edge of the material, stop the sewing machine. NOTE: The Needle Plate has both Metric and Inch Markings as an aid for guiding your fabric when sewing a seam. 6. First turn the handwheel toward you (counter-clockwise) until the needle is at its highest position. Raise the presser 6 foot, draw materials to the rear and cut off excess thread with the thread cutter located on the bottom of face cover as shown. NOTE: To secure the stitching and avoid raveling, press the reverse stitch switch and sew a few stitches at the start and end of the seam. KEEPING SEAMS STRAIGHT To keep the seam straight, use one of the numbered guide lines on the needle plate. The numbers indicate distance from the needle at its center position. The guide line on the bobbin cover plate is 1/4" (6mm) seam guide line which is used for piecing quilt blocks and also for narrow seams. 42 3/4" (19 mm) 5/8" (16 mm) 1/2" (13 mm) 3/8" ( 9 mm) 1/4" ( 6 mm)