Stihl HT 101 Product Instruction Manual - Page 23

Chain Lubricant, Filling Chain Oil Tank

|

View all Stihl HT 101 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 23 highlights

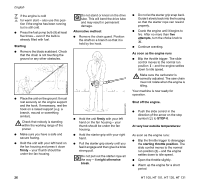

Closing the threaded filler cap Chain Lubricant English Filling Chain Oil Tank N Position cap. N Turn the cap clockwise as far as it will go and tighten it as securely as possible by hand. 200BA422 KN 390BA047 KN For automatic and reliable lubrication of the chain and guide bar - use only an environmentally compatible quality chain and bar lubricant. Rapidly biodegradable STIHL Bioplus is recommended. Biological chain oil must be resistant to aging (e.g. STIHL Bioplus) since it will otherwise quickly turn to resin. This results in hard deposits that are difficult to remove, especially in the area of the chain drive and chain. It may even cause the oil pump to seize. The service life of the chain and guide bar depends on the quality of the lubricant. It is therefore essential to use only a specially formulated chain lubricant. Do not use waste oil. Renewed contact with waste oil can cause skin cancer. Moreover, waste oil is environmentally harmful. Waste oil does not have the necessary lubricating properties and is unsuitable for chain lubrication. A full chain oil tank is sufficient for only half a tankful of fuel. Check the oil level regularly during cutting work. Never allow the oil tank to run dry. Preparations N Thoroughly clean the oil filler cap and the area around it to ensure that no dirt falls into the tank. N Position the machine so that the filler cap is facing up. HT 100, HT 101, HT 130, HT 131 21