Stihl HT 101 Product Instruction Manual - Page 29

Operating Instructions - spark plug

|

View all Stihl HT 101 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 29 highlights

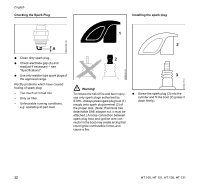

If the engine does not start Choke knob If you did not turn the choke knob to e quickly enough after the engine began to fire, the combustion chamber is flooded. N Turn the choke knob to e. N Set the slide control, lockout lever and throttle trigger to the starting throttle position. N Start the engine by pulling the starter rope briskly - 10 to 20 pulls may be necessary. If the engine still does not start N Move the slide control to STOP-0. N Remove the spark plug - see "Spark Plug". N Dry the spark plug. N Crank the engine several times with the starter to clear the combustion chamber. N Refit the spark plug - see "Spark Plug". N Move the slide control to START. N Set the choke knob to e - even if the engine is cold. N Now start the engine. Throttle cable adjustment N Check adjustment of throttle cable - see chapter on "Adjusting the Throttle Cable". Fuel tank run until completely dry N After refueling, press the fuel pump bulb at least five times - even if the bulb is filled with fuel. N Set the choke knob according to engine temperature. N Start the engine. English Operating Instructions During break-in period A factory-new machine should not be run at high revs (full throttle off load) for the first three tank fillings. This avoids unnecessary high loads during the break-in period. As all moving parts have to bed in during the break-in period, the frictional resistances in the engine are greater during this period. The engine develops its maximum power after about 5 to 15 tank fillings. During Operation Do not make the mixture leaner to achieve an apparent increase in power - this could damage the engine - see "Adjusting the Carburetor". Check chain tension frequently A new chain has to be retensioned more often than one that has been in use for some time. Chain cold Tension is correct when the chain fits snugly against the underside of the bar and can still be pulled along the bar by hand. Retension if necessary - see "Tensioning the Saw Chain". HT 100, HT 101, HT 130, HT 131 27