Stihl MS 193 C-E Product Instruction Manual - Page 42

Engine Management, Adjusting the Carburetor

|

View all Stihl MS 193 C-E manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 42 highlights

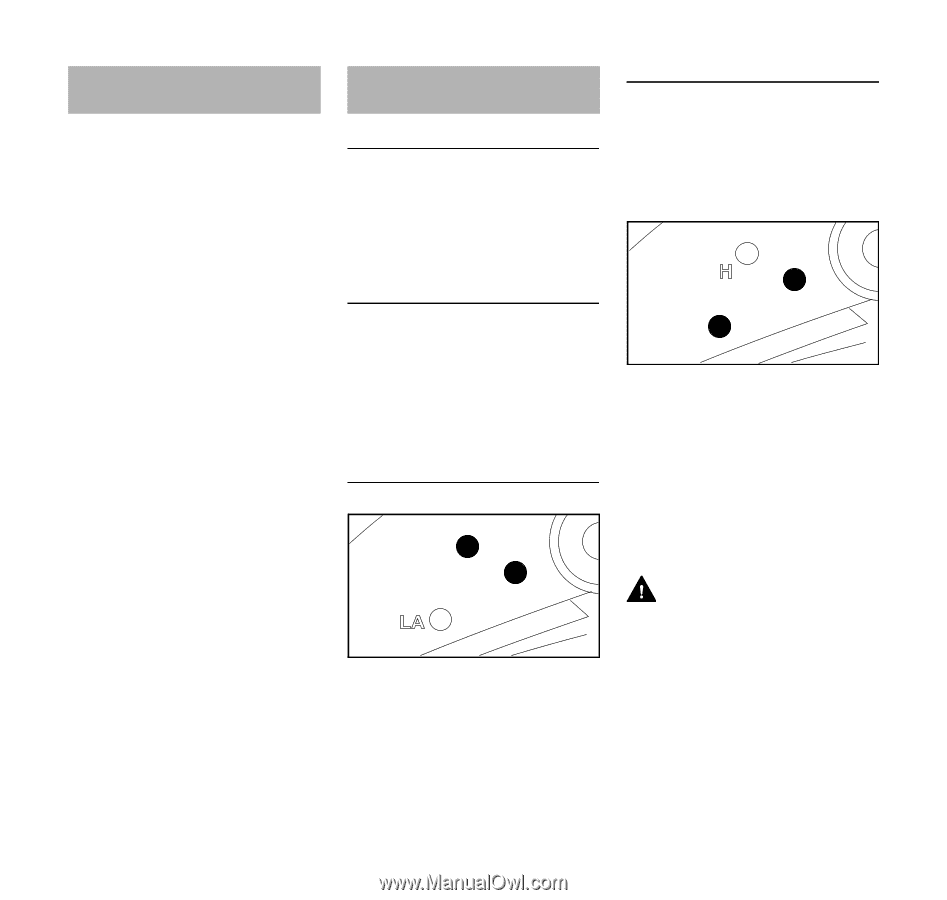

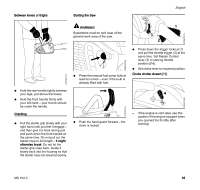

418BA010 KN 418BA011 KN English Engine Management Exhaust emissions are controlled by the design of the fundamental engine parameters and components (e.g. carburation, ignition, timing and valve or port timing) without the addition of any major hardware. Adjusting the Carburetor General Information The carburetor comes from the factory with a standard setting. This setting provides an optimum fuel-air mixture under most operating conditions. Preparations N Shut off the engine. N Check the air filter and clean or replace if necessary. N Check the spark arresting screen in the muffler and clean or replace if necessary. Standard setting H L N Turn high speed screw (H) counterclockwise as far as stop (no more than 3/4 turn). N Turn the low speed screw (L) clockwise as far as stop, then turn it back 1/4 turn. Adjust idle speed N Carry out the standard setting. N Start and warm up the engine. N Allow engine to idle for about 10 seconds before adjusting the idle speed. L LA Engine stops while idling N Turn the idle speed screw (LA) clockwise until the chain begins to run - then back it off 1 full turn Saw chain runs while engine is idling N Turn the idle speed screw (LA) counterclockwise until the chain stops moving - then turn it another full turn in the same direction. WARNING If the chain continues moving when the engine is idling, have your saw checked and repaired by your servicing dealer. Erratic idling behavior, poor acceleration (even though standard setting of low speed screw is correct) Idle setting is too lean 40 MS 193 C