HP ProLiant BL660c HP BladeSystem c-Class architecture - Page 8

Slim Form Factor

|

View all HP ProLiant BL660c manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 8 highlights

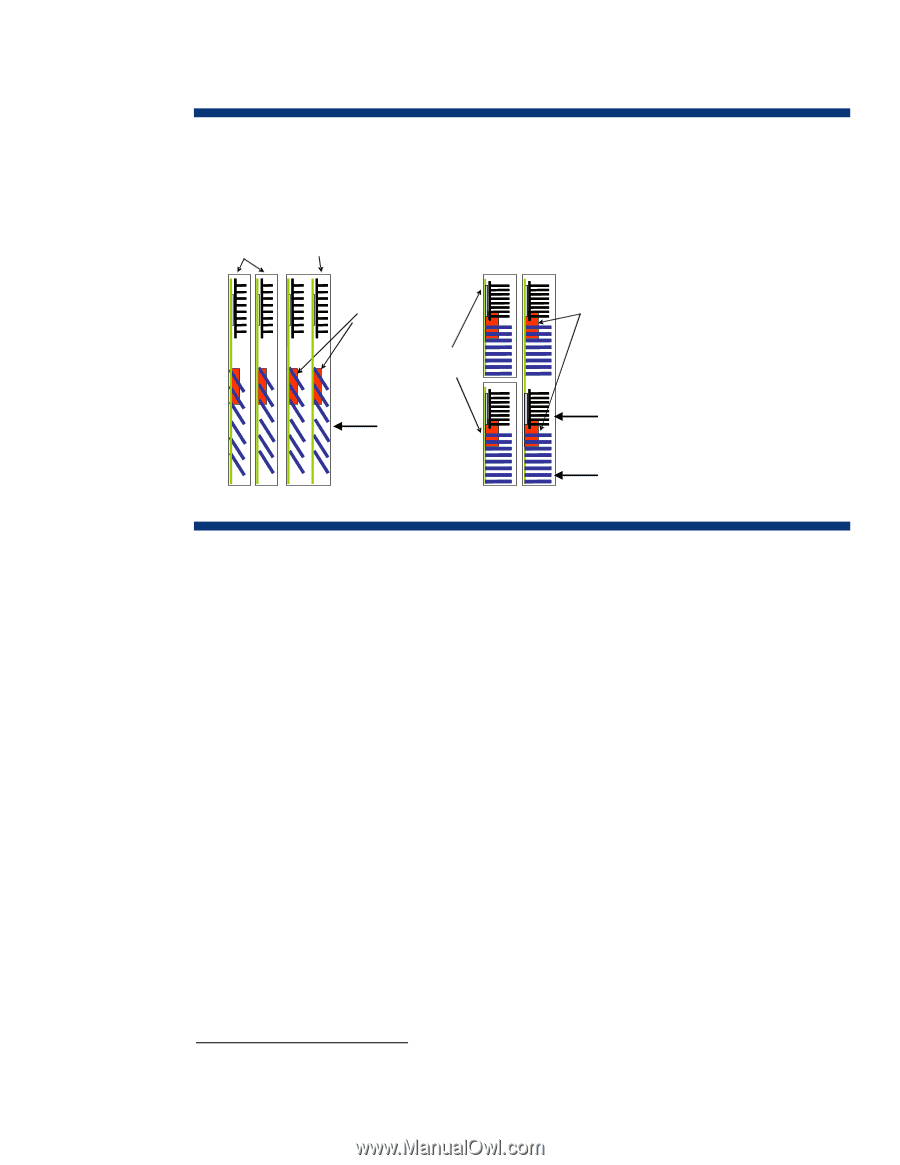

database or with mainstream, 2P blades for web or terminal services. Alternatively, customers can populate the enclosure with some mixture of the two form factors.1 Figure 4. Form factors evaluated by HP for the BladeSystem c-Class Slim Form Factor Wide Form Factor Single-Wide Blades Double-Wide Blade Backplane connectors on different PCBs Half-Height Blades Slanted memory DIMMs Full-Height Blade Midplane connectors on the same printed circuit board (PCB) Room for tall heat sink Vertical memory DIMMs Note that Figure 4 shows the vertical configuration that is used in the c7000 enclosure. For the rack model of the c3000 enclosure, the enclosure is rotated 90 degrees so that the blades slide into the enclosure horizontally rather than vertically. The HP configuration using wider device bays offers several advantages: • Supports commodity performance components for reduced cost, while housing a sufficient number of blades to amortize the cost of the enclosure infrastructure (such as power supplies and fans that are shared across all blades within the enclosure). • Provides simpler connectivity and better reliability to the NonStop signal midplane when expanding to a full-height blade because the two signal connectors are on the same printed circuit board (PCB) plane, as shown in Figure 4. • Enables the use of standard-height dual inline memory modules (DIMMs) in the server blades for cost effectiveness. • Provides improved performance because the vertical DIMM connectors enable better signal integrity, more room for heat sinks, and better airflow across the DIMMs. Using vertical DIMM connectors, rather than angled DIMM connectors, requires a smaller footprint on the PCB and provides more DIMM slots per processor. Having more DIMM slots allows customers to choose the DIMM capacity that meets their cost/performance requirements. Because higher-capacity DIMMs typically cost more per gigabyte (GB) than lower-capacity DIMMs, customers may find it more cost-effective to have more slots that can be filled with lower capacity DIMMs. For example, if a customer requires 16 GB of memory capacity, it is often more cost-effective to populate eight slots with lower cost, 2 GB DIMMs, rather than populating four slots with 4 GB DIMMs. With the availability of low-power memory options on some server blades, the BladeSystem c-Class offers a 1 The BladeSystem enclosures use a removable, tool-less divider to hold the half-height blades. When the shelf is in place, it spans two device bays, so there are some restrictions on how enclosures can be configured. 8