HP Superdome SX2000 Generic Site Preparation Guide, Fourth Edition - Page 18

Airflow, Row Orientation, Dust and Pollution Control

|

View all HP Superdome SX2000 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 18 highlights

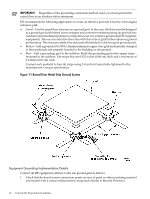

Airflow Ensure that separate hot and cold aisles are parallel to airflow patterns. • This recommendation causes cooling air to be released into cold aisles, where opposing rows have intake grills oriented. • Ensure that opposing row exhaust grills face each other, without cooling air. • A parallel orientation encourages low impedance airflow back to the HVAC. • Route cables underneath the floor to be parallel to the airflow to prevent airdams, if raised flooring is used. • Keep air throws from HVAC equipment to the heat loads they serve within 75 feet (22.86 m) of each other. Row Orientation Row orientation has an impact on the airflow, temperature, particulate contamination, and power distribution of the environment. Consider the following when planning equipment layout: • Use hot aisle (exhaust) and cold aisle (intake) orientation. • Route the airflow (air conditioned supply and return) to be parallel to the aisleways. • Adhere to the temperature and humidity standards located at: http://standards.corp.hp.com/ smc/hpstd/pdf/F-HP0000501.pdf. HP product specifications for temperature and humidity are measured at 1.9 inches (5.0 cm) from air intake center of device. Dust and Pollution Control Computer equipment can be adversely affected by dust and microscopic particles in the site environment. Specifically, disk drives, tape drives, and some other mechanical devices can have bearing failures resulting from airborne abrasive particles. Dust might also blanket electronic components such as printed circuit boards, causing premature failure due to excess heat or humidity buildup on the boards. Failures to power supplies and other electronic components can be caused by metallically conductive particles, including zinc whiskers. These metallic particles are conductive and can short circuit electronic components. Use every effort to ensure that the environment is as dust- and particulate-free as possible. See "Metallic Particulate Contamination" (page 19) for additional details. Smaller particles can pass through some filters and cause short life cycles in mechanical parts. Prevent small dust particles from entering the computer room by maintaining the air-conditioning system at a high static air pressure level. Other sources of dust, metallic, conductive, abrasive, and microscopic particles can be present. Some sources of these particulates are: • Subfloor shedding • Raised-floor shedding • Ceiling-tile shedding These particulates are not always visible to the naked eye. One method to determine their possible presence is to inspect the underside of the tiles. There are two types of flooring: a. galvanized - shiny - hot dipped: least susceptible for whiskers b. painted - dull - electroplating: most susceptible for whiskers 18 General Site Preparation Guidelines