HP Superdome SX2000 Generic Site Preparation Guide, Fourth Edition - Page 19

Metallic Particulate Contamination, must not exceed G1 mild levels of Group A chemicals at any time

|

View all HP Superdome SX2000 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 19 highlights

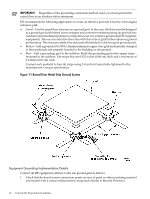

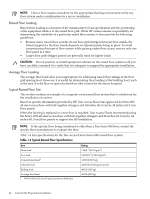

Keep the computer room clean by following these guidelines: • Establish a no-smoking policy. Particulates of cigarette smoke will not improve the operation or reliability of surrounding equipment. • Locate printers and paper products in a separate room to eliminate paper particulate problems. • Establish a no-eating-or-drinking policy. Spilled liquids can cause short circuits in equipment such as keyboards. • Use a dust-absorbent cloth mop rather than a dry mop to clean tile floors. • Use only HP-approved cleaners. In addition to dust and microscopic particles, chemical contaminants in the air can also damage electronics. Chemical contaminant levels in customer environments for HP hardware products must not exceed G1 (mild) levels of Group A chemicals at any time, as described in the current version of ISA-71.04-1985 Environmental Conditions for Process Measurement and Control Systems: Airborne Contaminants. See http://www.isa.org/ for more information. If the environment does not meet G1 levels, third party experts in remediation should be engaged to help bring the site into compliance. This work will include verifying contaminant levels and sources, as well as determining the most effective remediation techniques. Those may include filtration and abatement of the environment by qualified professionals to remove the contaminants. Table 1-1 Maximum Contaminant Gas Levels Maximum Group A contaminant gas levels in customer environments for class G1 in Table 3 of ISA-71.04-1985. Contaminant Gas Maximum Parts per Billion (ppb) H2S 3 SO2, SO3 10 Cl2 1 NOx 50 These values have been included for convenience and reflect the gas concentration levels in Table 3 of ISA-71.04-1985. The complete ISA document is available through the ISA website at: http://www.isa.org/. Metallic Particulate Contamination Metallic particles can be especially harmful around electronic equipment. This type of contamination can enter the data center environment from a variety of sources, including but not limited to raised floor tiles, worn air-conditioning parts, heating ducts, rotor brushes in vacuum cleaners, or printer component wear. Because metallic particles conduct electricity, they have an increased potential for creating short circuits in electronic equipment. This problem is exaggerated by the development of more dense circuitry of electronic equipment. Over time, very fine whiskers of pure metal can form on electroplated zinc, cadmium, or tin surfaces. If these whiskers are disturbed, they can break off and become airborne, possibly causing failures or operational interruptions. For more than 50 years, the electronics industry has been aware of the relatively rare but possible threat posed by metallic particulate contamination. During recent years, concern has increased regarding metallic particulate contamination in computer rooms where these conductive contaminants are formed on the bottom of some raised floor tiles. Although this problem is relatively rare, it can be an issue within your computer room. Because metallic contamination can cause intermittent or permanent failures on your electronic equipment, Environmental Elements 19